Gathering machines

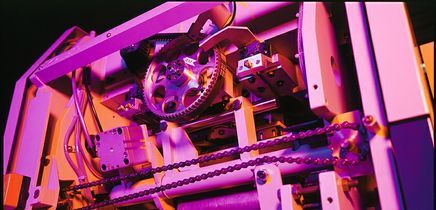

The gathering machines Sprinter s and Sprinter sXL are the reasonably priced versions of the Sprinter e and Sprinter eXL. Tried and tested machine building combined with modern design as well as latest development features for vacuum generation recommend the sprinters s and sXL as machines with an optimal cost/performance ratio. The machine is designed to be used as stand-alone machine or linked to a Wohlenberg perfect binder. The XL-series cover a larger format range and can be equipped with up to 32 stations.

The Streamer is based on a new machine concept marked by a high degree of modularity. This ensures that the Streamer will continue to meet process demands even for future product processing. Outstanding performance features of the new machine is the smooth production running and an easy and quick handling both during setup and during ongoing production.