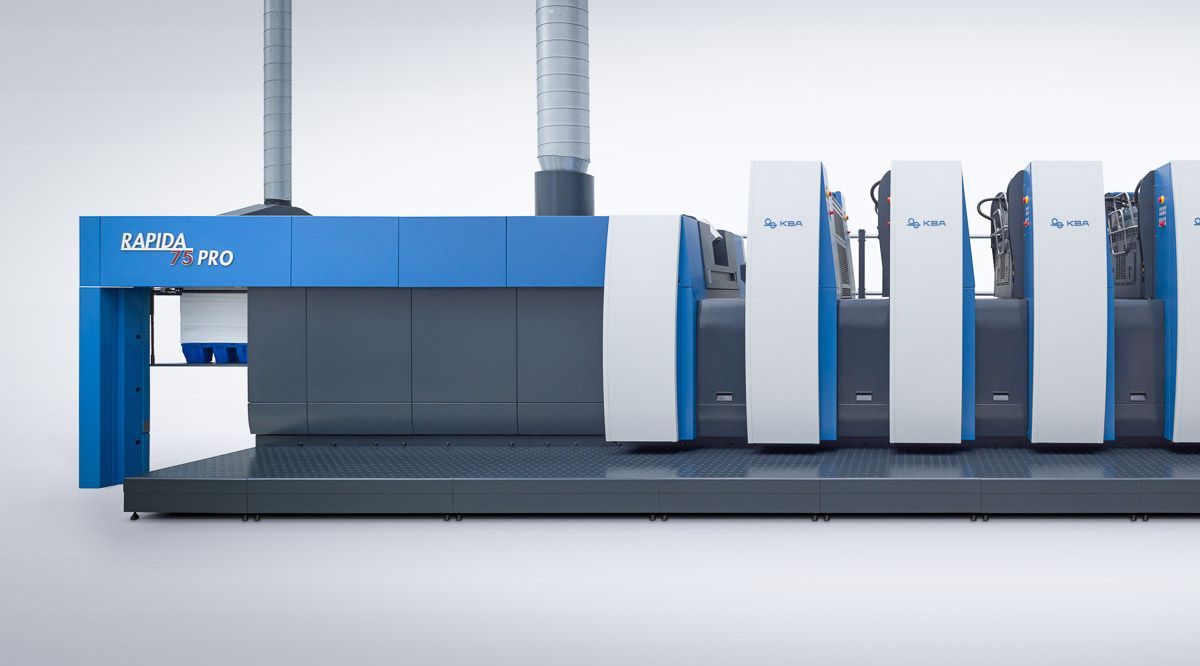

Rapida 75 Pro

The next generation in half format

With the Rapida 75 PRO, KBA is proud to present the latest generation of presses for half-format sheetfed offset. The new press is based on the proven mechanical platform of the predecessor series. The control concept is identical to that of all other Rapida models. Accordingly, the Rapida 75 PRO lends a further boost to operator convenience and offers a number of additional functions.

User-friendly TouchTronic operation

Thanks to TouchTronic, all operating functions can be accessed with a maximum of two taps on the corresponding screen buttons. “One-button job changes“ help to reduce makeready time by up to 50 per cent. All preselected functions are activated in time-optimised order at the press of a button.

The productivity of the Rapida 75 PRO has been raised yet another notch with standard printing speeds of up to 15,000 sheets/h. With the optional high-speed package, the maximum output increases further to 16,000 sheets/h. Up to 10 printing units, perfecting, an inline coater or even facilities for double coating permit a broad diversity of user-oriented configurations.

Highlights of the Rapida 75 PRO

- TouchTronic operator interface

- Greater automation and preset capabilities

- Comprehensive options for inline finishing

- Modern VariDry dryers systems, right up to LED-UVs

Productive and economical

Production on the Rapida 75 PRO permits considerable energy savings compared to other presses. From start to finish, it implements technical solutions geared to low energy consumption.

One example is the environment-friendly VariDry Blue dryer system in the extended delivery. Two heater units warm the process air to the drying temperature preselected at the console. Optimised hot air nozzles then spread the air over the whole surface of the substrate. The still only partially saturated air from dryer modules 1 and 2 is recirculated for further use in module 3 and in the swan neck. In this way, the energy consumption for drying can be reduced by up to 50 percent.

An optional energy management function measures the energy input at individual points of consumption and thus achieves even greater transparency.

Enlarged sheet format

The maximum sheet format on the Rapida 75 PRO is slightly larger than usual for a half-format press: 53 x 75 cm as standard, and even 60.5 x 75 cm as a special format. That also adds a little extra to the available printing area. The standard print format for straight production is 51 x 73.5 cm, and this increases to 58.5 x 73.5 cm with the special format.

In practice, the enlarged format means that printers who occasionally produce in US letter or typical magazine and catalogue formats can now plan 6-up layouts. Two extra copies on every sheet compared to other presses in this format class.

Even this small detail already boosts productivity by 50 per cent. That alone is reason to choose the Rapida 75 PRO for your B2 printing Needs.

Less space for more print

Despite the larger sheet format, the Rapida 75 PRO occupies only a minimum of floor space. Thanks to its compact design, it boasts a much smaller footprint than many other half-format sheetfed offset presses. The advantage for you: Where space in the printshop is at a premium and there is not room for other presses, it is often still possible to install a Rapida 75 PRO. And that nevertheless with adequate reserves for pile transport to and from the feeder and delivery.

The reduced footprint naturally has a further benefit, namely the positive effect on your space costs – and thus, in the end, on the cost calculations for your printed products. In other words, print production on the Rapida 75 PRO is extremely economical in every respect.

| Standard | Optional |

|

|

|

|---|---|---|---|---|

| Max. sheet format | 530 x 750 mm | 605 x 750 mm |

|

|

| Max. production speed 1) | 15.000 sheets/h | 16.000 sheets/h |

|

|

| Substrate thickness | 0,04 - 0,6 mm | 0,04 - 0,8 mm |

|

|

| Printing units | 2 - 10 | - |

|

|

| Fully automatic plate change FAPC | - |

ü |

|

|

| Perfecting | - |

ü |

|

|

| Venturi sheet guidance |

-

|

ü |

|

|

| CleanTronic washing systems | - |

ü |

|

|

| VariDry dryer systems | - |

ü |

|

|

| KBA logistics solutions | - |

ü |

|

|

| ErgoTronic console with TouchTronic interface |

ü |

- |

|

|

| Quality measurement and control systems | - |

ü |

|

|

| Remote maintenance module PressSupport 24 Sheetfed | - |

ü |

|

|

| Workflow solutions for printshop networking | - |

ü |

|

1 Dependent on individual processing parameters, e.g. inks and substrates used

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.