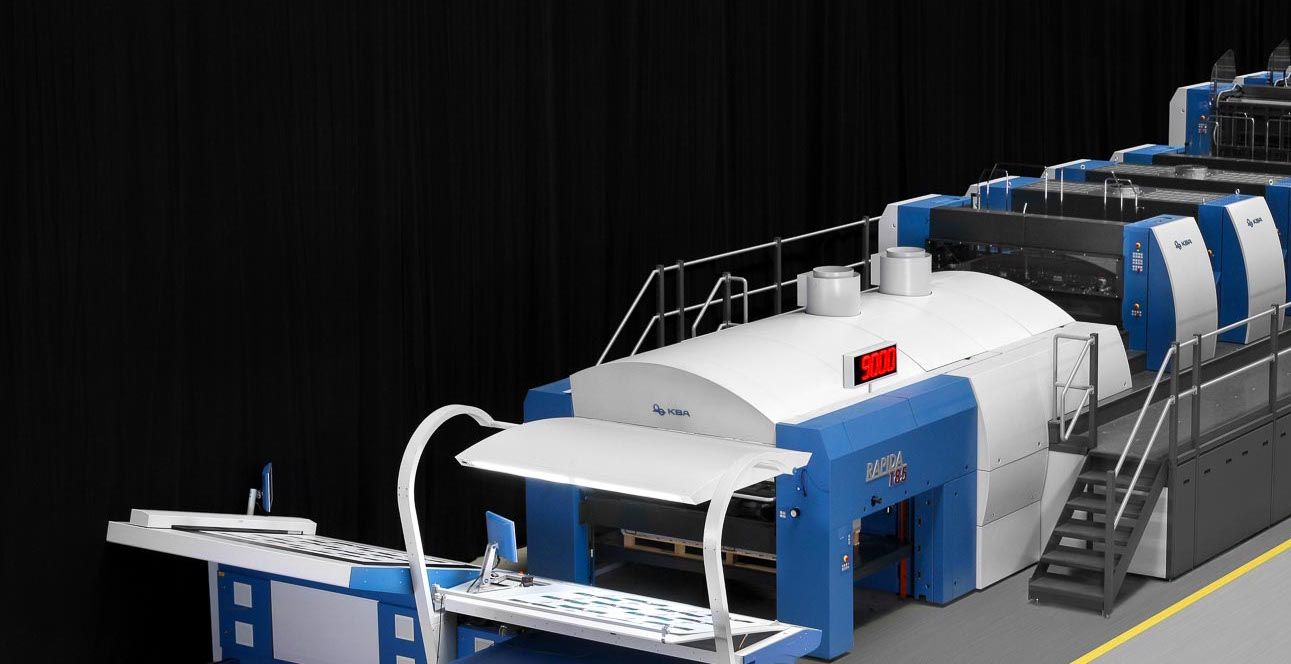

Rapida 185/205

Domain of Koenig & Bauer

The names Koenig & Bauer Rapida 185 and Koenig & Bauer Rapida 205 are practically synonyms for superlarge-format printing. When they were first launched a few years ago, they redefined the standards for sheetfed offset in XXL format. Even in the digital age, superlarge-format presses remain in demand, not only for poster printing, but also – and especially – for displays and king-size packaging.

New Fields of Business Thanks to Modern Technology

A maximum production format of 1.51 x 2.05 metres confirms the Rapida 205 as the largest sheetfed press in the world in terms of sheet size. With a sheet area in excess of 3 m2 and a maximum printing speed of 9,000 sheets/h, it is capable of delivering a printed area of almost 28,000 m2 per hour. That is a figure which no other sheetfed offset press can match.

The Most Important Features of the Rapida 185/205 at a Glance:

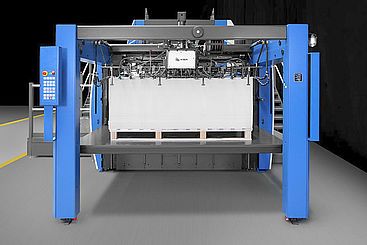

- DriveTronic feeder with automatic non-stop pile changing

- Sheet guiding for paper and board

- Full automatic plate change in 4 minutes

- Coating in all required dimensions

Fewer sections in poster production

Whether City Light, Mega Light, 18/1 billboard or one of many other formats, there are significantly fewer sections to each poster when printed on a Rapida superlarge-format press. A standard City Light poster can even be produced on a single sheet.

Minimisation of the number of sections is an essential key to economic success for any poster printer. With the frequently very short runs, after all, the makeready times for each new section soon mount up. It is thus a significant advantage that many poster types can be printed without divisions on the Rapida 185/205.

The superlarge-format presses from Koenig & Bauer also repay their investment very quickly in the printing of billboard posters. A typical 18/1 billboard requires only a four-sheet division. There are similarly fewer sections for all poster formats based on a 3-metre height, such as 40/1 superposters. In addition to the printing, subsequent hanging of the poster is also greatly simplified.

More possibilities for POS displays

Large-format POS displays are usually printed in several parts and then need to be pieced together, often by hand, to make up the final product. With the Rapida 185, and all the more so with the Rapida 205, however, even a man-size stand-up display can be printed in one piece. That drastically reduces job complexity both for the printer and at the conversion stage.

At the same time, the enlarged print format adds a host of new creative options for display Designers.

New approaches in packaging and book production

One field in which the Rapida 185 and Rapida 205 presses are able to play out their strengths is the production of high-volume packaging. Today, even large consumer goods such as televisions or vacuum cleaners are often delivered in attractive, full-colour printed boxes. Packaging, after all, is also an advertising medium – and one with which all buyers of the product concerned come into contact.

Book production is likewise a potential field of application for the superlarge-format Rapidas. Each sheet accommodates 72 pages of the classic book formats 21 x 28 cm (landscape) or 17 x 24 cm (portrait). The inline slitting facility (ICS) returns the format to accustomed and easily handled dimensions.

| Standard | Optional |

|

|

|---|---|---|---|

| Max. sheet format | 1300x1850 mm | - |

|

| Max. production speed 1) | 11.000 sheets/h | - |

|

| Substrate thickness | 0,1 - 0,8 mm | up to 1,6 mm |

|

| Printing units | 2 - 8 | 8+ |

|

| Fully automatic plate change FAPC |

ü |

- | |

| CleanTronic washing systems |

ü |

- | |

| VariDry dryer systems | - |

ü |

|

| KBA logistics solutions | - |

ü |

|

| Quality measurement and control systems | - |

ü |

|

| Remote maintenance module PressSupport 24 Sheetfed | - |

ü |

|

| Workflow solutions for printshop networking | - |

ü |

|

1 Dependent on individual processing parameters, e.g. inks and substrates used

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.