Cross-linking per bind-com®

Prior-ranking goal of every entrepreneur’s acting is to realize a profit. The question is: Does a cross-linking of processes in book bindery contribute to this target?

The bookbinder must, nowadays, offer his customers significantly more engineering performance than formerly - and that for less money. A cost-benefit analysis based on key data from the branch will show that in a lot of bookbinderies money is rather exchanged than earned.

A sensible cross-linking can help a bookbinder to reduce cost and effort and increase the efficiency of the processes involved. Increasing the productivity enables the bookbinder to again achieve a reasonable profit level.

But – how does a sensible cross-linking look like?

For example:

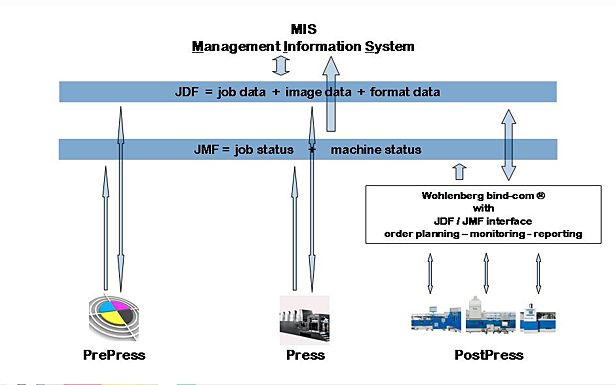

- A cross-linking along the entire value added chain of a product – from Prepress via Press to PostPress – this means in a bookbindery the whole finishing sector.

- A cross-linking which likewise includes the administration- as well as the production processes of the bookbindery, i.e. the entire process of job processing from calculation, folding and perfect binding to product cost analysis and issuing an invoice.

- A cross-linking with a management information system (MIS) as the core piece, which is the initial- and end point of all information flow and which controls and monitors the entire job processing.

- A cross linking using neutral, manufacturer-spanning standards, as they are specified by the CIP4 initiative, in fact the Job Definition Format (JDF) and the associated Job Messaging Format (JMF). Only through standards as the JDF, an open system architecture can be guaranteed, maintaining the bookbinder’s independence from any specific suppliers – be it software- or machine– wise.

- Isolated solutions of some manufacturers, requiring that the entire software and all linked machines are bought from one source, should be regarded sceptically. Experience with other branches, e.g. the CIM initiative in the eighties has clearly shown that isolated solutions are expensive in the long run, too inflexible and doomed to failure.

The cross-linking of a Wohlenberg perfect binding system with a MIS is realised by means of the technical control station bind-com®. The technical control station evaluates the picked-up JDF files, and returns (per JMF messages) the current job- and machine conditions of all linked machines to the MIS.

This kind of data transfer prevents the machine controls from being burdened with reading- and sending jobs. Bind-com ®. evaluates all header data and process parameters out of the JDF files, checking the parameters as to completeness and feasibility. During the check all necessary machine settings are taken from the JDF files and are sent, after job release, to the Navigators (machine-operating interfaces).

With a Wohlenberg perfect binding system linked to a MIS the following profit reserves can be activated:

Reduction of setup- and down-times during the individual production processes by:

Avoiding to do a job twice.

Repeated input of job data on the various Navigator-machine operator interfaces is no longer required. Particularly during the setup of a complete perfect binding line, when ZTM, perfect binder and three-knife trimmer need to be set separately, this is of a significant saving potential. Additionally the savings should be considered which incur parallel in the administrative field, between pre-calculation, job planning and post-calculation.

Avoiding to repeat tasks.

E.g. in case of periodicals or interrupted jobs – the data of once produced or similar jobs can, if needed, be reloaded from the data base and transferred to the machines. Entire process steps can be ignored or, at least, significantly be reduced due to the fully motorized process. Merely a quality check is necessary.

Reduction of the transfer- respectively holding time between several production processes.

Can be realised by the dynamic process-spanning job planning- and control in MIS. The basis are the always updated status messages of all systems involved in the JMF standard workflow.

Improvement of the process quality by reliable job- and process data.

All data originate from one source, i.e. the management information system (MIS). This prevents that mistakes slip in, caused by multiple input of identical data.

Analysis based on facts.

The permanently recorded and methodically saved job- and processing data (machine data) can be evaluated business-orientated. First time a qualified post-calculation is possible, based on automatically recorded job- and machine data. This increases the safety significantly when it comes to future project calculations.

Shorter processing time and more precise time-on delivery by better transparency along the entire value added chain.

Quick intervention.

By real-time feedback signals of the machine station to the MIS, failures in the job management are immediately detected.

Optimal co-ordination.

Changes, e.g. in the sequence of job processing, can be initiated online. This makes changes known to all involved in the process, thus sparing coordination meetings and time-consuming co-ordination measures

Interface to Internet for improved job management and acquisition of further additional orders.

Job monitoring.

Monitoring the entire order along all the steps of the value added chain, from printing shop to bookbindery can, efficiently, only be realised per Internet. Only this way it is possible to exchange information, real-time, with sufficient detail accuracy, particularly when all companies involved are located a long way from each other. Downtimes caused by changes are recognized in time and rescheduling made possible.

New business fields.

Connection to the internet will open further business fields. Already now deals can be secured by auction in the internet. Probably tomorrow virtual companies are created, taking on bulk orders which then in turn are assigned to the relevant participating partners. This will increase the degree of utilization in the key processing segments, as well as the productivity of the bookbinders business. That virtual companies are not just an imagination was proven by other business branches, e.g. the woodworking industry.

Generally it can be said that by the introduction of a JDF workflow system, not only a significant time- and cost-saving effect is achieved, but also quality improvements. Within the Wohlenberg programme all machines of the E-series with Navigator operator-interface are ‘bind-com®’/JDF-compatible via the technical control station.

For using all advantages of an integrated workflow it is absolutely necessary that all value-added -relevant machines, involved in this process, provide a JDF-connection.

bind-com®

is a registered trademark of Wohlenberg Buchbindesysteme GmbH

ConditionPro®

is a common project of Kuhnke Automation GmbH & Co. KG in Malente and Wohlenberg Buchbindesysteme GmbH in Verden. ConditionPro® is a registered trademark of the Kuhnke company.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.