Fasson-ماشین چسب زنی

ماشین چسب زنی و مونتاژ Display که Display به کارخانه ها امکان افزایش نرخ تولید را با نفرات کم تر، تعمیر و نگهداری کمتر، کنترل دقیق تر کیفیت و کاهش زمان تحویل را عرضه می کند.

مناسب برای چسب زنی طرح، لبه و نوار - حرکت زمان بندی شده - انواع مواد، blanks ها مانند blanks های دایکات و غیره از مقوای معمولی و کاروگیت.

مناسب برای چسب زنی طرح، لبه و نوار - حرکت زمان بندی شده - انواع مواد، blanks ها مانند blanks های دایکات و غیره از مقوای معمولی و کاروگیت.

مناسب برای چسب زنی نواری و لب به لب تمام مواد از قبیل

• تغذیه time chain - مناسب برای blanks های ساده و پیچیده از نظر هندسیtime chain feeding – suitable for geometrically simple and complicated blanks (die-cuts)

• رجیستر دقیق برای چسب زنی

• پهنای کار: ۲۰۵۰ میلیمتر

• ساختار یکپارچه و منطقی

• آماده سازی راحت و سریع شامل stereo (block) assembly – by using the first blank for carrying the stereo

• شستشوی راحت و سریع با آب

• 2-blank operation possible – dependent on blank width

• اپراتوری آسان، حداقل تعمیر و نگهداری، اقتصادی

• کنترل صفحه: تشخیص blanks های جا مانده فشار نورد شمارنده را کمتر می کند.

• کارایی: از ۲۰-۴ blanks در دقیقه - تغذیه دستی: بسته به اندازه و ابعاد هندسی blanks

• fast and direct adjustment of stencil cylinder, also during machine operation by gear wheel assembly or servo

تنظیم راحت و رجیستر کردن موقعیت stereo توسط کنترل الکترونیکی ماشین برای مدل SFAM ۲۰۱۶، حتی حین کار ماشین

پهنای کار: ۲,۰۵۰ mm

خروجی (blanks در دقیقه): کار ۱stream: حداکثر ۲۰ تکه در دقیقه

ضخامت Blank : از حدود ۰/۵ میلیمتر تا ۲۰ میلیمتر

چسب: چسب سفید استنسیل (Adhesive: Adhesive: stencil gluing white resin (dispersion)

شستشو/ تمیز کردن واحد چسب زنی: حدود ۵-۳ دقیقه

Cleaning / wash up of gluing unit: approx. 3 – 5 min.

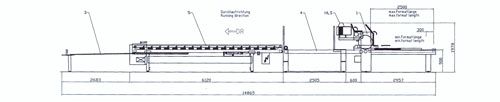

ابعاد مدول های ماشین:

: حدود ۴ در ۲/۴ متر (طول در عرض)، ۲۲۰۰ کیلوگرم

: حدود ۴ در ۲/۴ متر (طول در عرض)، ۲۲۰۰ کیلوگرم

ایستگاه مونتاژ: حدود ۲/۶ در ۲/۴ متر (طول در عرض)، ۲۲۰۰ کیلوگرم ·

· assembly station: approx. 2.6 x 2,2m (l x w), 1,400 kg

Pressure band: حدود ۶/۱ در ۲/۴ متر (طول در عرض)، ۲۵۰۰ کیلوگرم

ولتاژ: ۵۰ هرتز، سه در ۴۰۰ ولت

برق مصرفی: حدود ۴ /۵ / ۱,۵ کیلو وات · Pressure band: approx. ۶,۱ x ۲,۴m (l x w), ۲,۵۰۰ kgVoltage: ۳ x ۴۰۰ Volt, ۵۰ HzPower requirement: approx. ۴ / ۵ / ۱,۵ kW

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.