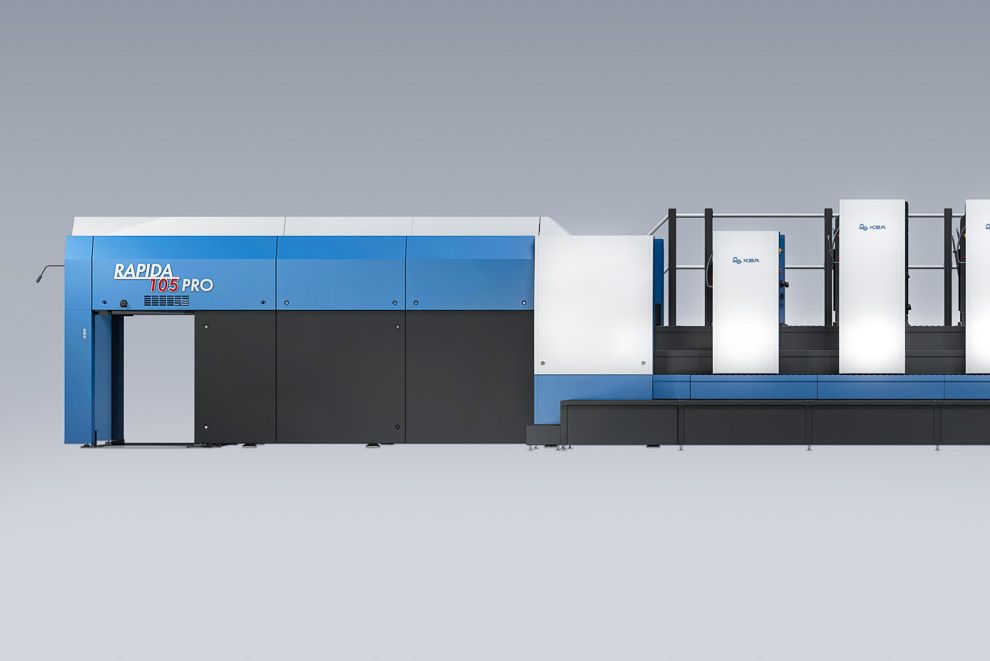

Rapida 105 Pro

For the upper performance segment in medium format

Best in its class – true to this motto, the KBA Rapida 105 PRO has established itself in the upper performance segment of B1 sheetfed offset. Practically unlimited configurations for perfecting applications, diverse possibilities for inline finishing and a sheer endless range of equipment options permit individually tailored solutions, and supply the key to new market segments and business models.

Future-oriented and productive

Whether for commercial work, packaging or labels – the Rapida 105 PRO is an efficient means of production in every printing environment. Look forward to extensive automation and comprehensive preset capabilities. The Rapida 105 PRO offers everything which belongs to modern sheetfed offset.

Highlights of the Rapida 105 PRO

- Perfecting with up to 10 printing units

- Inline finishing, such as double coating or numbering, perforating or corona units

- ErgoTronic console with comprehensive management functions

- Automatic non-stop systems with optional integration into pile logistics

Tailored configuration

The features of the Rapida 105 PRO can be tailored precisely to the production requirements of an individual business setting.

As a packaging press, it is frequently placed on raised foundations and expanded with accessory packages for board handling, corrugated board, plastic films or UV printing. The incorporation of coaters and drying units enables high-quality effect finishes in an inline process. Cold foiling, too, is becoming increasingly popular. Automatic non-stop systems and the integration into pile logistics installations permit uninterrupted production.

For commercial production, the high-performance perfecting unit is especially interesting. The conversion between straight printing and perfecting modes is accomplished fully automatically in less than two minutes. The special sheet guiding after perfecting ensures ultimate print quality on both sides of the sheet, and a video system allows the printer to monitor sheet travel inside the press.

The Rapida 105 PRO demonstrates further exemplary flexibility with a wide range of additional automation options to augment the already comprehensive basic configuration. At the end of the day, your particular requirements determine an economically meaningful level of automation.

Comprehensive preset capabilities

From the feeder, via the printing units to the delivery – all components of the Rapida 105 PRO can be preset using CIP3/CIP4 data from pre-press. That simplifies handling and shortens makeready times.

The DriveTronic feeder loads numerous pre-defined format and air settings automatically. The job changeover program on the ErgoTronic console sends these data directly to the digital controllers on the press. Makeready on the feeder runs simultaneously with other makeready processes. That saves time and Money.

The setting procedure is identical for the infeed and for the sheet travel in the printing units. A combination of blower modules and Venturi guide plates provides for air-cushioned sheet transport and contact-free sheet travel through the whole press. At the delivery, this concept ensures reliable and scratch-free pile formation even at high production speeds. All digital settings on the AirTronic delivery can also be saved for later use as preset values.

High productivity

With printing speeds up to 17,000 sheets/h, the Rapida 105 PRO belongs to the upper performance segment of the medium format class.

Parallel makeready processes – for example during washing – enhance productivity. Job-specific preselection of an appropriate washing program achieves perfect cleaning results in the shortest possible time. Rapida 105 PRO also offers a solution to match every requirement when it comes to plate changing. You can choose between a convenient automated variant and a fully automatic system which completes plate changes in less than three minutes.

Fast makeready pays off all the more where run lengths are becoming shorter and shorter. The practice-oriented automation concept of the Rapida 105 PRO allows individual users to specify the process steps which are to run automatically, and thus how quickly they are back in production after job changes. The Rapida 105 PRO is a good investment in the satisfaction of your customers and in your competitiveness on the print market.

| Standard | Optional |

|

|

|

|---|---|---|---|---|

| Max. sheet format | 740 x 1.050 mm | 750 x 1.050 mm, 780 x 1.050 mm |

|

|

| Max. production speed 1) | 17.000 sheets/h | - |

|

|

| Substrate thickness | 0,06 – 0,7 mm | 0,04 - 1,2 mm, 0,2 - 1,4 mm |

|

|

| Printing units | 2- 10 | 10+ |

|

|

| Fully automatic plate change FAPC | - |

ü |

|

|

| Perfecting | - |

ü |

|

|

| CleanTronic washing systems |

ü |

- |

|

|

| VariDry dryer systems | - |

ü |

|

|

| AirTronic delivery with dynamic sheet brake |

ü |

- |

|

|

| KBA logistics solutions | - |

ü |

|

|

| ErgoTronic console with TouchTronic interface |

ü |

- |

|

|

| Quality measurement and control systems | - |

ü |

|

|

| Remote maintenance module PressSupport 24 Sheetfed | - |

ü |

|

|

| Workflow solutions for printshop networking | - |

ü |

|

|

1 Dependent on individual processing parameters, e.g. inks and substrates used

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.