Innovation Lined-Road from the First Cylinder Press to Digital Print

In August 2017, Koenig & Bauer AG (KBA) in Würzburg celebrated its 200th anniversary. The world's first press-building workshop of 1817 has since blossomed into a globally successful manufacturing group with a unique portfolio of solutions for the printing industry. Anniversary was an ideal occasion to review past achievements and to present the visions which will determine the company's strategy and market position in the third century of its history.

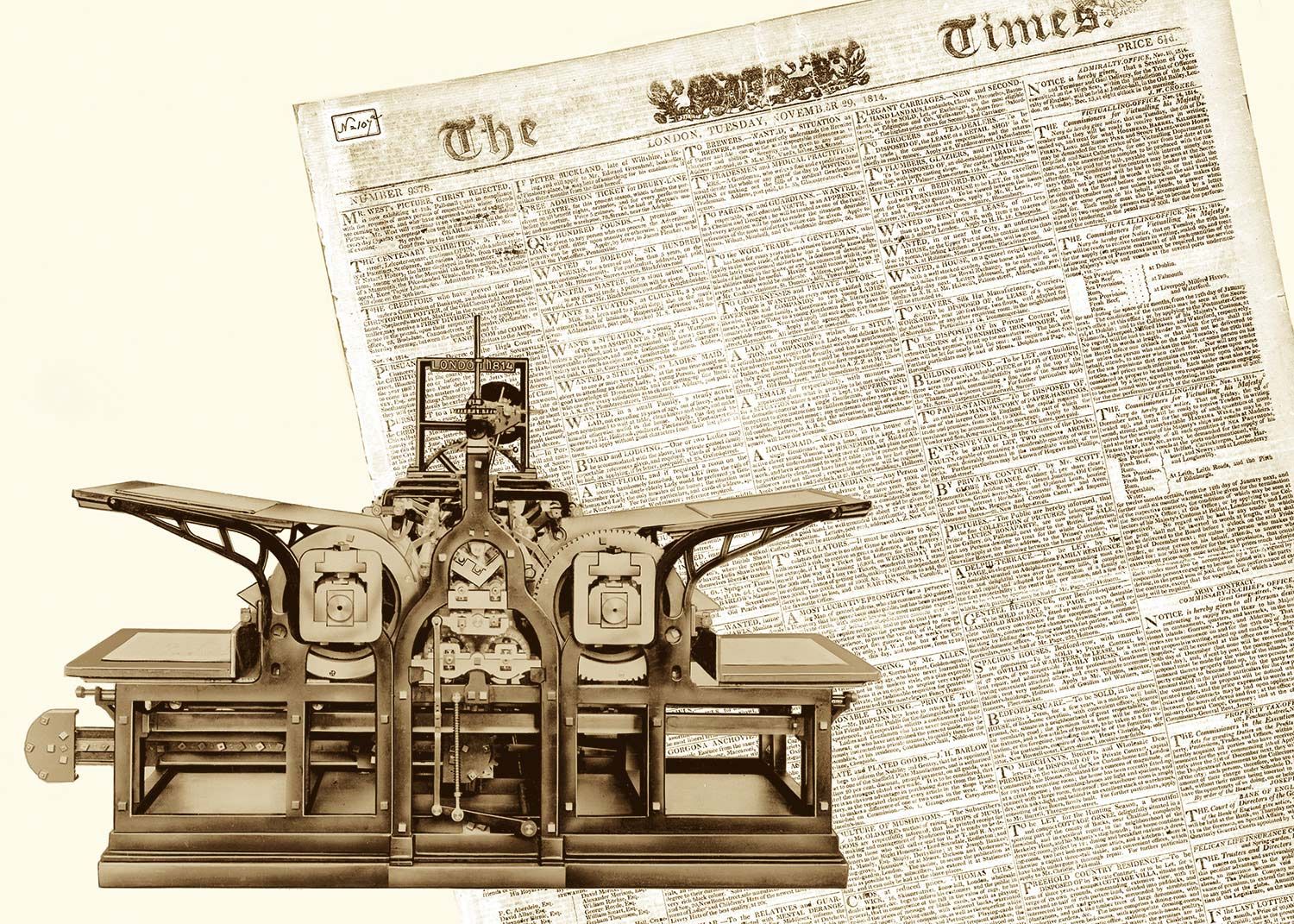

Breakthrough in London

In the early 19th century, Friedrich Koenig travelled to London in 1807 to realise his idea of a steam-driven printing press. While there, he met an engineer Andreas Bauer, and in November 1814, The Times became the first newspaper to be printed on their double-cylinder press. This laid the foundations for printing on an industrial scale and for access to print media for a much broader section of the population.

Production in a former monastery

On 9th August 1817, Friedrich Koenig and Andreas Bauer signed a contract establishing Schnellpressenfabrik Koenig & Bauer in a monastery in Oberzell near Würzburg, and in 1823, the Haude und Spenersche Zeitung in Berlin was the first newspaper on the European continent to be printed on presses from Oberzell.

Friedrich Koenig died in 1833. His widow Fanny Koenig and his former business partner Andreas Bauer continued his work. New presses were developed and the one-hundredth press was already delivered in 1838. A number of ambitious young workers moved away to found their own businesses. In this sense, Oberzell can be considered the cradle of German printing press manufacture. The company's foundation period came to an end with the death of Andreas Bauer in 1860.

1876: The era of web printing begins

The first webfed press was supplied to a newspaper in Magdeburg in 1876. In 1895, the 5000th cylinder press left the factory.

From 1895 and through into the 1920s, the course of the company was

shaped by Constantin Koenig and the founder's grandson Albrecht Bolza. In 1901,

a new factory was built at the site today occupied by the company headquarters.

The 225 metre long production hall was one of the largest in

Germany at that time.

Destruction and rebuilding

After the First World War, Koenig & Bauer survived the period of hyperinflation in the 1920s thanks to the newly developed Iris collect press for coloured banknotes. In March 1945, bombs and artillery shells destroyed the Würzburg factories. Reconstruction began in 1946.

1952: Success story of security printing

Cooperation with securities printing expert Gualtiero Giori began in 1952. A further important milestone was the arrival of a talented young design engineer named Dr. Hans-Bernhard Schünemann, the son of a Bremen publishing family, in 1951

Successful presses Condor and Rotafolio

Despite the growing offset competition in the 1960s and 70s, Koenig & Bauer retained the proven letterpress technology for its sheetfed and webfed presses for a relatively long time. Alongside the Rembrandt sheetfed gravure press and banknote presses developed together with De La Rue Giori, the two-revolution Condor and the Rotafolio sheetfed press for wrap-around plates were extremely successful all over the world.

High-performance in sheetfed offset since 1974

The first sheetfed offset press, the half-format Koebau-Rapida 0, was presented at drupa in 1967. The medium-format Koebau-Rapida III followed in 1969. Both ran at speeds up to 8,000 sheets per hour. The Koebau-Rapida SR III launched in 1974 was almost twice as fast at 15,000 sheets per hour. The presses of other major manufacturers did not achieve such performance until much later.

In 1986, Koenig & Bauer launched the Rapida 104, a unit-type press designed for high flexibility and printing speeds up 15,000 sheets per hour. Production was transferred to the new subsidiary KBA-Planeta AG in 1992. The current Rapida 106, for example, has defined the benchmarks in medium format with speeds up to 20,000 sheets per hour, extremely fast job changeovers and configurations comprising up to 19 printing and finishing units.

Today’s large-format series Rapida 145 and 164 are the successors to the Rapida 142 and 162 presses which were developed jointly by the Radebeul design engineers and their colleagues from Würzburg in the 1990s.

Pioneer of new technologies

In the same way that the Würzburg engineers ventured new approaches to webfed printing.

When it comes to innovative processes for inline finishing, ecological printing, direct printing on corrugated board or – most recently – LED-UV drying, KBA Sheetfed has regularly acted as a pioneer. The entry into the post-press market in 2016 and the announcement of the digital sheetfed press VariJET 106 at drupa open up further prospects.

World first in webfed printing

The era of web offset presses from Würzburg began with the Commander in 1969.. At the beginning of the 1990s, this trend was answered with the four-high tower presses Journal and Colora.

At drupa 2000, a new trend towards compact highly automated newspaper presses was heralded by the KBA Cortina, which stood less than 4 metres high

Media upheavals and realignment

Already in the early 1990s, the World Wide Web was taking its first tentative steps and new digital competitors entered the print arena. Faced with growing online competition, and especially due to the world financial crisis, the market for new webfed offset presses collapsed dramatically in 2008. Koenig & Bauer responded by turning attention to the digital process from 2011, and presented its first inkjet web press, the RotaJET 76, at drupa 2012. Today, with the RotaJET VL series for decor printing and the T1100 S manufactured on behalf of the American HP Corporation for the production of corrugated packaging, the largest digital web presses in the world are produced in Würzburg.

Early diversification

The acquisition of Albert-Frankenthal AG and of a majority stake in Planeta Druckmaschinenwerke in the early 1990s.

The acquisition of Swiss partner De La Rue Giori SA in Lausanne in 2001 secured KBA’s pole position in banknote printing. The purchase of Metronic GmbH in 2004 opened the door to the important market for industrial coding systems. The acquisitions of Bauer + Kunzi and LTG Print Systems, and the subsequent merger into KBA-MetalPrint GmbH in 2006, established KBA as the number one in metal decorating. And with KBA-Kammann GmbH as a global leader for the decoration of glass containers, alongside flexible packaging specialist KBA-Flexotecnica S.p.A, KBA has since 2013 further expanded its portfolio for the diverse packaging segment. A similar purpose was served by the takeover of Spanish die-cutter manufacturer Iberica in 2016.

This early diversification has helped KBA to master the structural upheavals which have rocked the branch much better than other press manufacturers.

Print technologies for every eventuality

Today, analogue and digital KBA technologies are used to print, finish and process products such as banknotes, metal cans, books, brochures, displays, decor, labels, glass and plastic containers, board and film packaging, catalogues, laminates, magazines, tyres, cables, smart cards, advertising flyers, newspapers and many more besides. Practically all common printing and finishing technologies are involved. This diversity creates unique know-how, and continues to drive innovations, new applications and new partnerships.

Innovation Lined-Road from the First Cylinder Press to Digital Print

205 Years Koenig & Bauer

Koenig & Bauer Technology