Depart

Abbey printer switches to KODAK SONORA X Process Free Plates and modernizes platemaking operations with a KODAK TRENDSETTER Q800 Platesetter

Münsterschwarzach Abbey in Schwarzach, near Würzburg (Germany), was founded as a nunnery in the year 780. Re-acquired by the Missionary Benedictines in 1913, it is today home to around 100 monks. In keeping with the monastic rules, the abbey maintains a number of businesses and workshops providing work not only for monks but also for some 300 secular employees. Among the economically strongest of these businesses is Benedict Press: with 25 people on the payroll, the printer specializes in end-to-end production of high-quality books (including coffee-table books), art catalogs, calendars, posters and a whole series of other print products.

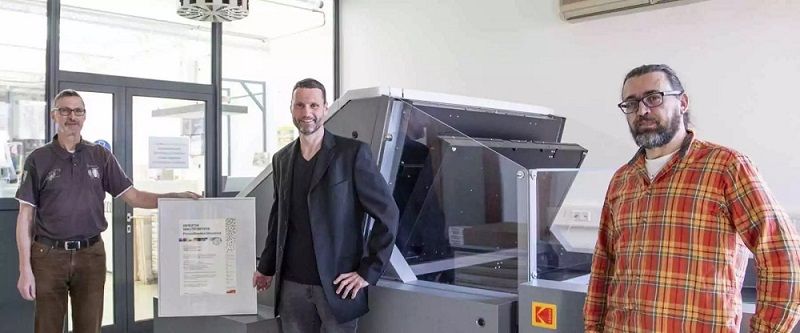

Dietmar Michel (Prepress Manager, left), Michael Blass (Production Manager, center) and Manfred Weidinger (Digital Sheet Assembly and Costing) next to the KODAK TRENDSETTER Q800 Platesetter with the renewed PSO certificate.

Priority for “green” economics – printing included

From left to right: Former printshop manager Br. Alfred Engert OSB (Ordo Sancti Benedicti), Abbot Michael Reepen and Michael Blass, currently Production Manager at Benedict Press.

“We’re passionate TRENDSETTER users. That platesetter was the best possible publicity for Kodak because it kept going without any problems for all those years and never once let us down,” says Blass. “That’s why we definitely wanted another Kodak. However, in order to make plate imaging more efficient – and our operators’ lives easier – we were keen to invest in a fully automatic system that is also capable of in-line plate punching.”

With this in mind, the abbey printer chose a KODAK TRENDSETTER Q800 Platesetter with KODAK SQUARESPOT Imaging Technology that is equipped with the optional Single Cassette Unit (SCU) as well as an in-line punch. The printer has two plate trolleys for the SCU, each with a maximum capacity of 120 plates including slip sheets. All of this adds up to an automated CTP process with the most popular plate sizes for the two large presses.

Benedict Press Improves Sustainability with Innovative Kodak Products

Kodak News