For over 125 years, engineers at KAMA have been developing high-quality finishing die cutters and folder-gluers for the global market.

As a well-established, reliable partner for cutting and finishing processes, we offer a wide range of profitable solutions for small and medium-sized conventional print runs as well as for digital printing. With more than 500 installations in 80 countries the innovative KAMA machines "made in Germany" are in demand around the world - in the commercial print market and also in packaging.

From the company’s early days with 20 employees when it was founded after the reunification of Germany, it has now grown to 120 members of staff.

Packaging market: growth in a niche sector

It goes without saying that, for a long time, the primary purpose of packaging was to protect the product inside – but now it is also all about creating visually strong packaging with a focus on recognition factor and brand staging. While conventional advertising is increasingly losing relevance, packaging is steadily becoming a more important tool for influencing purchase decisions. Today’s customer is much more likely to be impressed by visual and tactile experiences than by abstract promises of happiness. The result: packaging is one of the few growth segments in the print market, and it is currently conquering a brand new segment – the market for small print runs.

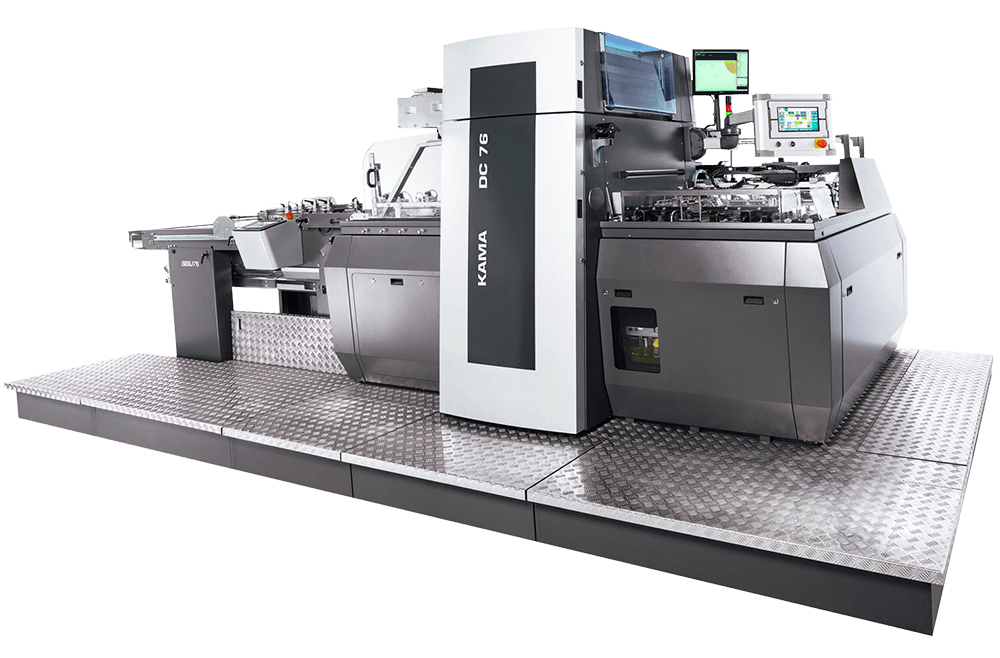

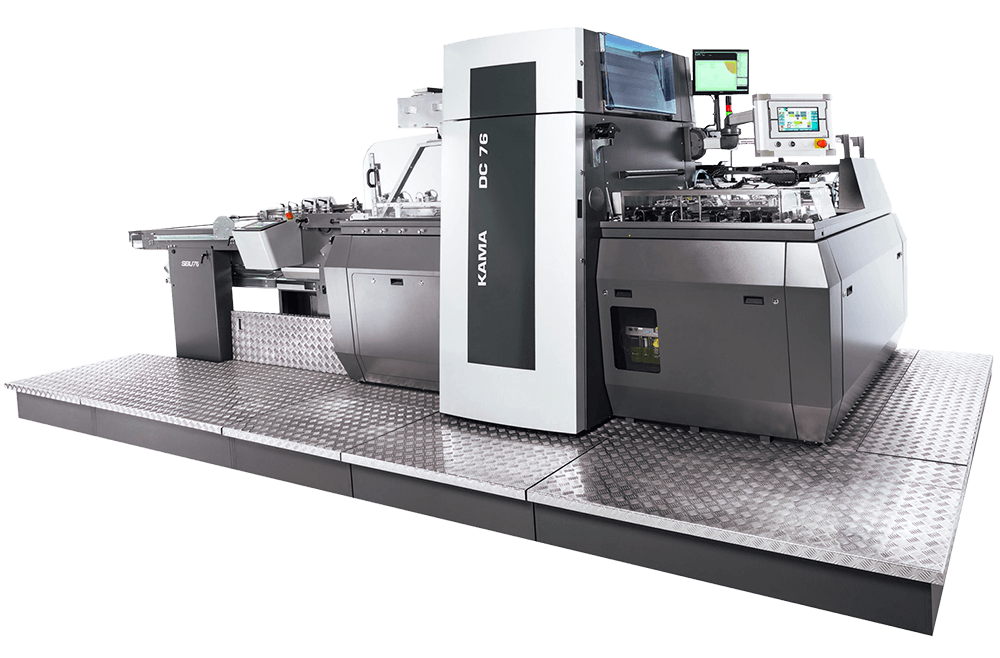

KAMA DC 76 foil

KAMA CPX

Commercial printing: on a mission to wow customers

For a long time, commercial print shops faced one particular challenge: producing short runs at low cost. But barely any supplier in the market today will survive by focusing on price alone. More and more companies that specialise in commercial print jobs have therefore chosen a different strategy. They are taking the plunge into the premium segment and expanding their portfolio with post-press offerings and automated final production for folding and gluing.

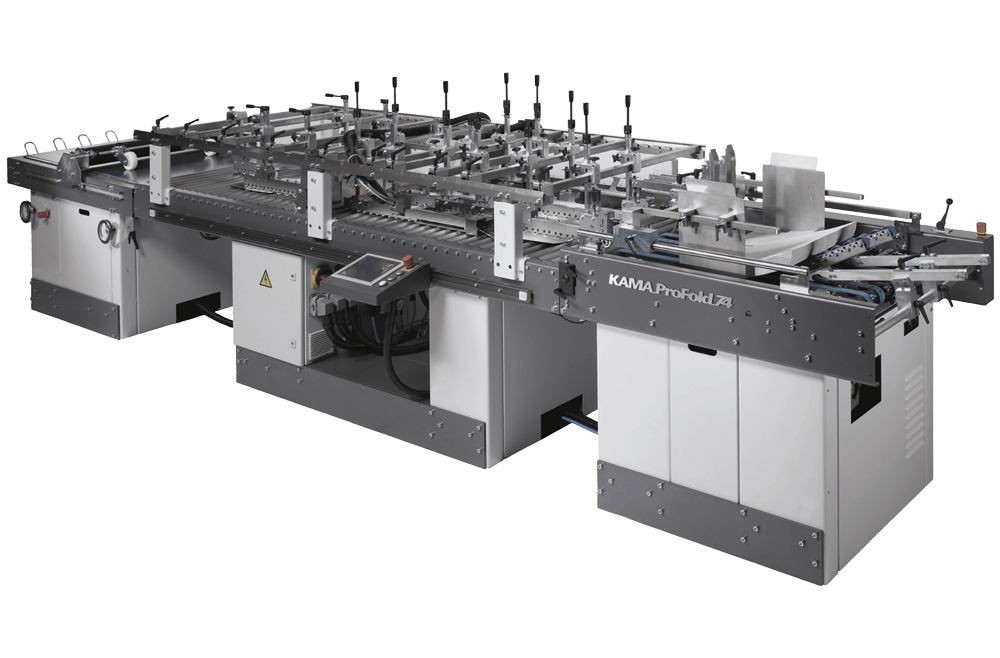

With an investment in a compact all-rounder like the ProCut 76 Foil or the ProFold 74 from KAMA, you will benefit in three different ways:

Renowned performance and greater added value

Increased flexibility in post-press and finishing

Keeping all aspects of production in-house ensures reliable quality and shortens delivery times

ProCUT dc 76 Foil

ProFold 74