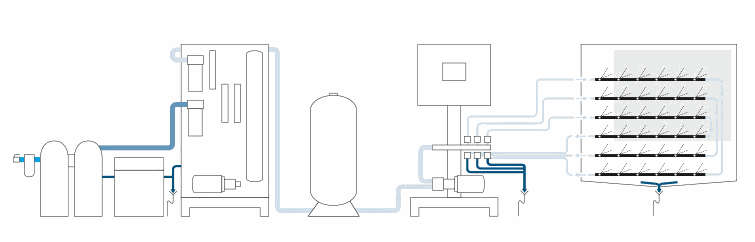

High- Pressure Air Humidification For Central Ventilation Systems

Duct Humidification

Water Supply Connection ½"

Internal Thread With Stopcock

Water Inlet Filter

Water Softening Unit

Salt Container

Waste Water Connection

Reverse Osmosis Unit

Pressure Tank

High-Pressure Air Humidification

Solenoid Valve: Humidification

Solenoid Valve: Pressure Relief

and Flushing

High-Pressure Pipeline Stage 1–3

Nozzle Holders

Drop separator

(to be provided on site)

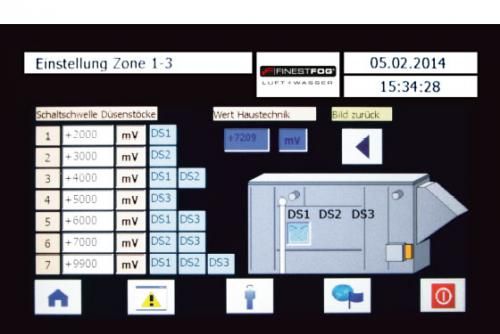

The Control Unit (duct)

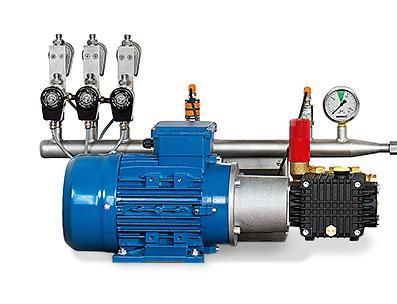

The Pump (duct)

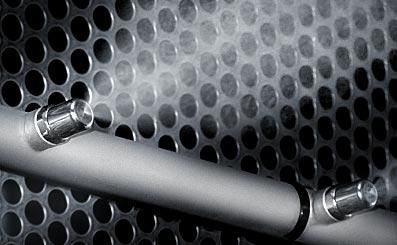

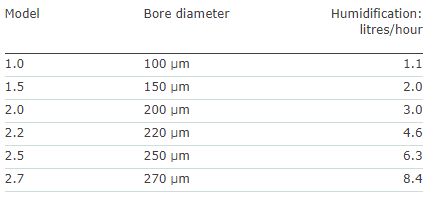

The Nozzle (duct)

st.

FINESTFOG duct humidification is precisely controllable. The controller, with its integrated Siemens PLC and clearly arranged touchscreen, receives the control signal, converts it to a seven-stage cascade connection and meters the humidification of the HVAC system. Here the patented FINESTFOG high-pressure nozzles atomize the water, with no drips, to a superfine mist. The desired air humidity is maintained with high precision.

Air washers repeatedly circulate any unevaporated water – with all the negative impacts on hygiene: the need to use chemicals, high desludging rates, elaborate UV disinfection and a very high maintenance effort. By contrast, FINESTFOG keeps the condensate portion low and only fresh ultra-pure water from the FINESTFOG reverse osmosis system is used. A periodic flushing cycle and the integrated UV sterilization complete the hygiene concept of the FINESTFOG duct humidification.

Steam humidifiers are known for their high energy consumption. Air washers, too, with their circulating pumps are big energy consumers. by contrast, FINESTFOG air humidification saves energy. Frequency-controlled pumps, cascade connections and high efficiency all contribute to significantly lower energy costs compared with other systems

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.