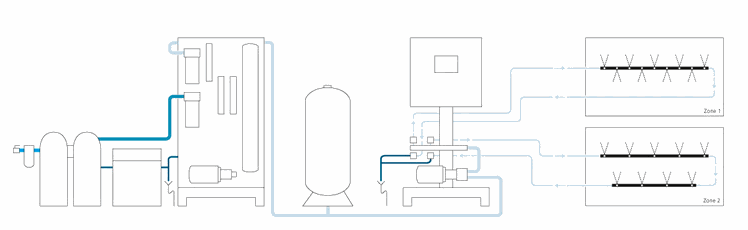

Direct Humidification

Braille embossing on the dot

Water supply connection ½"

Internal thread with stopcock

Water inlet filter

Water softening unit

Salt container

Waste water connection

Reverse osmosis unit

Pressure tank

Pressure relief and flushing

High-pressure air humidification

High-pressure hose zone 1 and 2

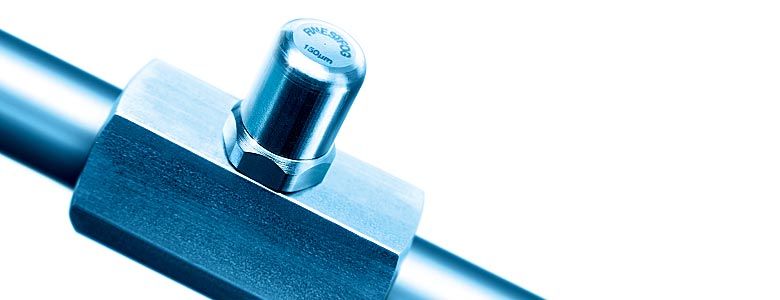

Humidifier pipes with

high-pressure nozzle

Control Unit

The Pump