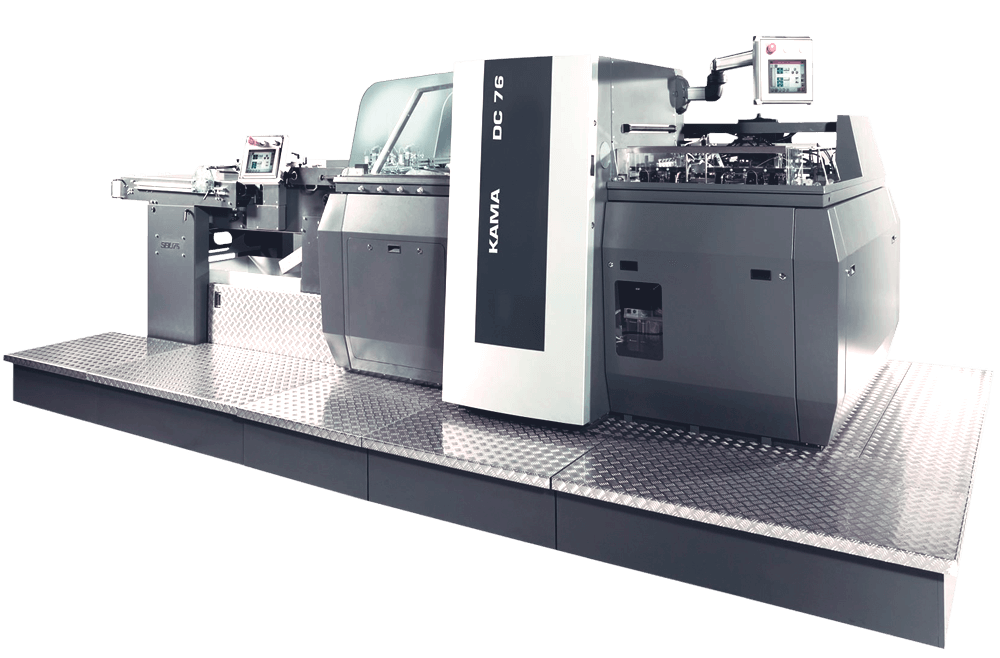

دی سی - 76- فویل

ماشین دایکات دی سی۷۶ فویل

کارهای پس از چاپ و خدمات تکمیلی کارآمد برای بسته بندی

اگر هدف شما تولید جعبه های مقوایی در تیراژ پایین و با کیفیت بالا و در عین حال مقرون به صرفه می باشد، ماشین دایکات DC۷۶ Foil این کار را به خوبی انجام می دهد. زمان سریع تعویض کارها، رجیستر دقیق با سیستم اتورجیستر و سیستم هات فویل و هولوگرام با فویل، برای ارائه کارهای باکیفیت و پاسخ به نیازهای مختلف کاربران کافی است.

از همه مهم تر این ماشین یک مزیت مهم اقتصادی دارد: هیچ ابزاری برای قرار دادن مقواهای مورد استفاده در جعبه ها بر روی ماشین DC۷۶ Foil لازم نیست. برای جعبه های مقوایی کیفیت بالا مورد استفاده در لوازم آرایشی، مصارف قنادی و شیرینی پزی، محصولات بهداشتی و دارویی با هولوگرام، ماشین DC۷۶ Foil برای تمام کارهای پس از چاپ و روی مواد چاپ شده به روش دیجیتال، مناسب می باشد.

نقاط قوت

کاربردهای متنوع

انواع کارهای پس از چاپ و خدمات تکمیلی

حداقل زمان آماده سازی

تعویض سریع کارها

قرار دادن کار روی صفحه ماشین بدون نیاز به ابزار خاص

قرار دادن سریع کار روی صفحه ماشین

دقیق ترین رجیستر

هر کیفیتی که صاحبان برند انتظار دارند

کارآمدی بالا با فویل داغ

با توان بیشتر و ایده آل برای کاربرد فویل

حداکثر سرعت انجام کار

ماشین با تمام توان کار می کند.

قابلیت کار با شبکه "پرینت ۴/۰"

گردش اطلاعات از پیش از چاپ تا پس از چاپ

طراحی جمع و جور

انجام کارهای متنوع در یک فضای کوچک

مشخصات ماشین دی سی۷۶فویل

مواد چاپی مورد استفاده و مشخصات:

کاغذ

۱۰۰ - ۸۰۰ گرم/مترمربع

مقوا؛ مقوای کاروگیت میکروفلوت

حداکثر ۱,۵۰۰ گرم /مترمربع

پلاستیک

حداکثر اندازه کاغذ ۷۶۰x

حداکثر اندازه کاغذ

۷۶۰در ۶۰۰ میلیمتر

حداقل اندازه کاغذ

۲۷۹در ۲۱۰ میلیمتر

سرعت*

۵,۵۰۰ ورق در ساعت

نیروی برش (با سروُ موتور)

۱۸۰ t

ابعاد (طولx عرض)

۷۴۳x ۵۸۵ میلیمتر

فاصله پنجه

۱۰ میلیمتر

ابعاد (طول در عرض)

۴/۸۷x ۲/۶۹متر

بسته به ماده مورد استفاده، اندازه ورق و اطلاعات فنی برای انجام کار

مواد چاپی مورد استفاده و مشخصات:

| کاغذ | ۱۰۰ - ۸۰۰ گرم/مترمربع |

| مقوا؛ مقوای کاروگیت میکروفلوت | حداکثر ۱,۵۰۰ گرم /مترمربع |

| پلاستیک |

حداکثر اندازه کاغذ ۷۶۰x |

| حداکثر اندازه کاغذ | ۷۶۰در ۶۰۰ میلیمتر |

| حداقل اندازه کاغذ | ۲۷۹در ۲۱۰ میلیمتر |

| سرعت* | ۵,۵۰۰ ورق در ساعت |

| نیروی برش (با سروُ موتور) | ۱۸۰ t |

| ابعاد (طولx عرض) | ۷۴۳x ۵۸۵ میلیمتر |

| فاصله پنجه | ۱۰ میلیمتر |

| ابعاد (طول در عرض) | ۴/۸۷x ۲/۶۹متر |

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.