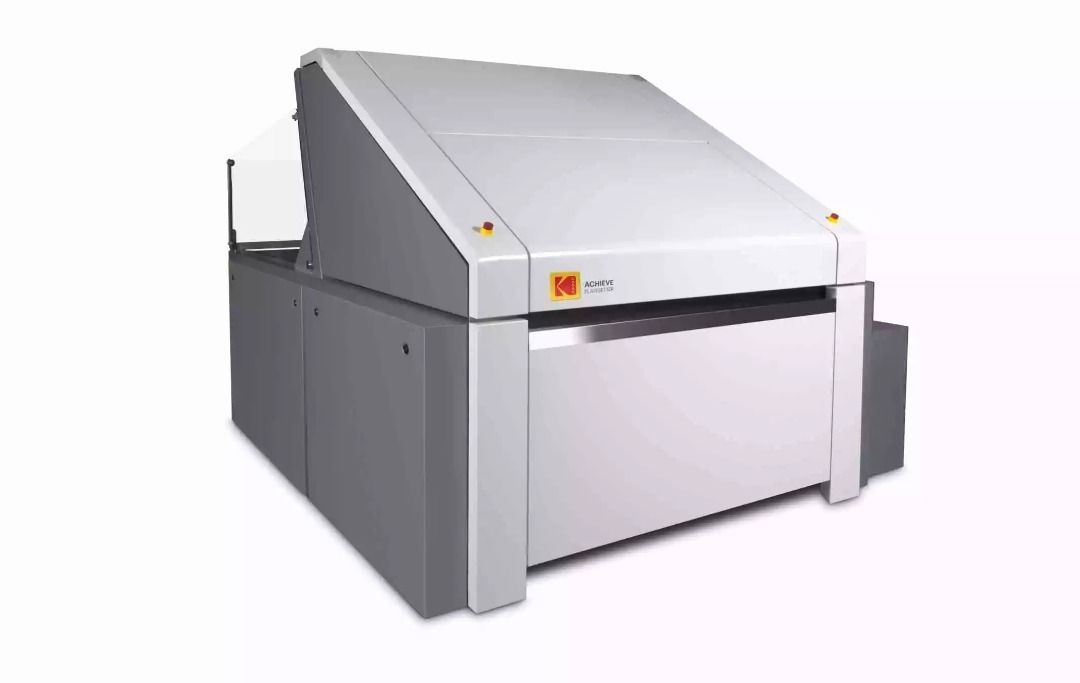

اچیو T400/T800

ارزش و کیفیتی استثنایی

پلیت سترهای اچیو ۴۰۰T/۸۰۰T کداک محکم و قابل اطمینان هستند. این پلیت سترها ثبات تکنولوژی حرارتی کداک را در قیمتی پایین به همراه دارند. این پلیت سترها برپایه پلتفرم موفق پلیت سترهای ترندستر کداک ساخته شده اند و با طیفی از امکانات اتوماسیون و سرعت عرضه می شوند.

بارگذاری اتوماتیک پلیت ها

پلیت ستر های اچیو ۴۰۰T/۸۰۰T یک امکان اتوماسیون دیگر دارد که به رشد کسب و کارها کمک می کند. واحد چند کاسته (MCU) با بارگذاری و برداشتن پلیت به طور اتوماتیک، ظرفیت ۴۸۰ پلیت را دارد. با MCU می توان تا چهار اندازه مختلف پلیت را به صورت آنلاین به کار برد. بدین ترتیب بهره وری و تولید بالا می رود. پنج امکان اتوماسیون وجود دارد که از بین آنها می توانید آنچه را که منطبق بر شرایط کسب و کارتان است، انتخاب کنید.

امکان کنترل پلیت ستر از راه دور

از هر مکانی که هستید می توانید با استفاده از موبایل خود و اپلیکیشن "موبایل CTP کنترل" کداک در کنار پلیت ستر خود باشید.

با کمک پیامها و هشدارهای این برنامه، قادر به مشاهده کار دستگاه ها، مدیریت کارهای چاپی و کار انداختن چند پلیت ستر از هر مکانی هستید.

این امکان روی تمام مدل های جدید پلیت سترها مگنوس، اچیو و ترندستر کداک وجود دارد.

تکنولوژی به اثبات رسیده ی تصویرسازی حرارتی

در پلیت سترهای اچیو از تکنولوژی تصویرسازی TH۵ کداک استفاده می شود. با تکنولوژی تصویرسازی حرارتی می توان به راحتی از پلیت های بدون نیاز به ظهور استفاده کرد و تاثیرات مخرب محیط زیستی را کاهش داد.

در پلیت سترهای اچیو از تکنولوژی تصویرسازی TH۵ کداک استفاده می شود. با تکنولوژی تصویرسازی حرارتی می توان به راحتی از پلیت های بدون نیاز به ظهور استفاده کرد و تاثیرات مخرب محیط زیستی را کاهش داد.

مصرف برق کمتر، ضایعات کمتر

پلیت سترهای اچیو می توانند بخش مهمی از استراتژی توسعه پایدار هر شرکتی باشند. مدل های جدید آن در مقایسه با مدل های قدیمی و همچنین پلیت سترهای سایر شرکت ها انرژی کمتری مصرف می کنند بدون اینکه روی میزان یا کیفیت تولید تاثیر بگذارند. پلیت سترهای اچیو T۴۰۰/T۸۰۰ در هنگام تصویرسازی فقط ۴۰۰ وات برق مصرف می کنند که تا ۹۳% کمتر از دستگاه های سایر شرکت هاست. اگر پلیت های بدون نیاز به ظهور سونورا را با پلیت سترهای اچیو به کار ببرید، در مصرف انرژی، آب و دارو در بخش پیش از چاپ صرفه جویی خواهد شد و در بخش چاپ د.نیز با پلیت های دقیق و باثبات از میزان ضایعات کم می شود.

پلیت سترهای اچیو می توانند بخش مهمی از استراتژی توسعه پایدار هر شرکتی باشند. مدل های جدید آن در مقایسه با مدل های قدیمی و همچنین پلیت سترهای سایر شرکت ها انرژی کمتری مصرف می کنند بدون اینکه روی میزان یا کیفیت تولید تاثیر بگذارند. پلیت سترهای اچیو T۴۰۰/T۸۰۰ در هنگام تصویرسازی فقط ۴۰۰ وات برق مصرف می کنند که تا ۹۳% کمتر از دستگاه های سایر شرکت هاست. اگر پلیت های بدون نیاز به ظهور سونورا را با پلیت سترهای اچیو به کار ببرید، در مصرف انرژی، آب و دارو در بخش پیش از چاپ صرفه جویی خواهد شد و در بخش چاپ د.نیز با پلیت های دقیق و باثبات از میزان ضایعات کم می شود.

| مشخصات عمومی | |||

|---|---|---|---|

| تکنولوژی | لیزر ۸۳۰ نانومتر، درام خارجی | ||

| امکانات اختیاری برای اتوماسیون |

استاندارد: بارگذاری پلیت و برداشتن آن به صورت نیمه اتوماتیک برداشتن اتوماتیک پلیت (اختیاری): بارگذاری پلیت به صورت اتوماتیک و هدایت آن به پروسسور پلیت و استکر به صورت اتوماتیک، امکان اختیاری چرخاندن پلیت اتو لودر (اختیاری): بارگذاری پلیت و برداشتن آن به صورت اتوماتیک تا ۸۰ پلیت و برداشتن کاغذهای بین پلیت ها به طور اتوماتیک، (۰/۳ میلیمتر)؛ امکان اختیاری چرخاندن پلیت واحد تک کاسته (اختیاری): بارگذاری پلیت و برداشتن آن به صورت اتوماتیک تا ۱۲۰ پلیت و برداشتن کاغذهای بین پلیت ها به طور اتوماتیک؛ (۰/۳ میلیمتر)؛ امکان اختیاری چرخاندن پلیت واحد چند کاسته (اختیاری): بارگذاری پلیت و برداشتن آن به صورت اتوماتیک تا ۴۸۰ پلیت در ۴ کاست که هر کدام گنجایش ۱۲۰ پلیت هم اندازه و هم ضخامت (با کاغذهای بین پلیت ها) را دارد. می توان با ۴ اندازه پلیت به طور همزمان کار کرد. کاست موردنظر به طور اتوماتیک از طریق برنامه انتخاب می شود. استاندارد: ۲ کاست، اختیاری: ۴ کاست. امکان اختیاری چرخاندن پلیت. |

||

| امکان پانچ همزمان |

تا ۱۰ هد پانچ قابل استفاده است. پانچ موردنظر از لیست پانچ ها انتخاب می شود. براساس مشخصات ماشین چاپ، نوع پانچ موردنظر از برنامه گردش کار کداک انتخاب می شود. (اختیاری) فقط قسمت جلوی پلیت را می توان پانچ کرد. Optional automatic punching is operated according to press profile selected from the KODAK Workflow Punch is available on the front edge of the plate only Automatic punch system adjustment for centering of plate |

||

| پلیت های مورد استفاده |

پلیت های حرارتی بی نیاز به ظهور سونورا- کداک پلیت های حرارتی الکترامکس - کداک پلیت های حرارتی الکترا ایکس دی- کداک پلیت های حرارتی اچیو ایی ام - کداک پلیت های حرارتی کاپری کورن جی تی- کداک پلیت های حرارتی اسورد - کداک پلیت های حرارتی تریلیان اس پی- کداک |

||

| مشخصات عملکردی | |||

| T400پلیت ستر | T800پلیت ستر | ||

| Throughput at 2400 dpi3,4 plates per hour (pph) |

For plate size 724 x 838 mm

S speed = 22 pph F speed = 28 pph |

For plate size 1,030 x 838 mm

S speed = 16 pph F speed = 22 pph |

|

| قابلیت تکرار | ± 5 microns between two consecutive exposures on the same plate left on the drum | ||

| دقت | ± 20 microns between two plates imaged on the same device | ||

| رجیستر | ± 25 microns between image and plate edge | ||

| امکان اتصال به نرم افزار گردش کار | Standard KODAK Print Console with TIFF Downloader Software included; connects to KODAK PRINERGY Workflow and most third-party workflow systems. JDF/JMF Connectivity Option enables functionality in the Print Console software to provide job and device status. | ||

| مشخصات تصویر سازی | |||

| T400پلیت ستر | T800پلیت ستر | ||

| رزولوشن | 2400 dpi or 1200 dpi | ||

| ترام سازی | 200 lpi max line screen; Optional: 36-micron KODAK STACCATO Screening | ||

| حداکثر اندازه پلیت طول درام در عرض آن | 838 x 990 mm | Standard: 838 x 1,143 mm Auto Unload/Autoloader/SCU/MCU: 838 x 1,118 mm | |

| حداقل اندازه پلیت طول درام در عرض آن | Standard: 267 x 215 mm Auto Unload/Autoloader/SCU/MCU: 330 x 270 mm | Standard: 267 x 215 mm Auto Unload/Autoloader/SCU/MCU: 330 x 270 mm | |

| حداکثر اندازه تصویر | 827.9 x 990 mm | Standard: 827.9 x 1,143 mm Auto Unload/Autoloader/SCU/MCU: 827.9 x 1,118 mm | |

| مشخصات فیزیکی | |||

| اندازه (H x W x D) /وزن |

Standard: 160 x 200 x 120 cm / 650 kg

Auto Unload: 170 x 200 x 128 cm / 762 kg Autoloader: 184 x 200 128 cm / 796 kg SCU: 186 x 233 x 231 cm / 1,158 kg MCU: 191 x 233 x 254 cm / 1,837 kg In-Line punch system option: 102 x 151 x 120 cm / 177 kg For long unload table with plate rotation option: height becomes 210 cm, and 53 cm is added to the depth. Add 10 kg to weight. |

||

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.