Q400Throughput at 2400 dpi |

Q800Throughput at 2400 dpi |

Integrated punch enhances automation

Speed

Q400: 75 plates per hour

Q800: 68 plates per hour

eamless integration with KODAK Solutions

Time Tested Technology

| General specifications | ||

|---|---|---|

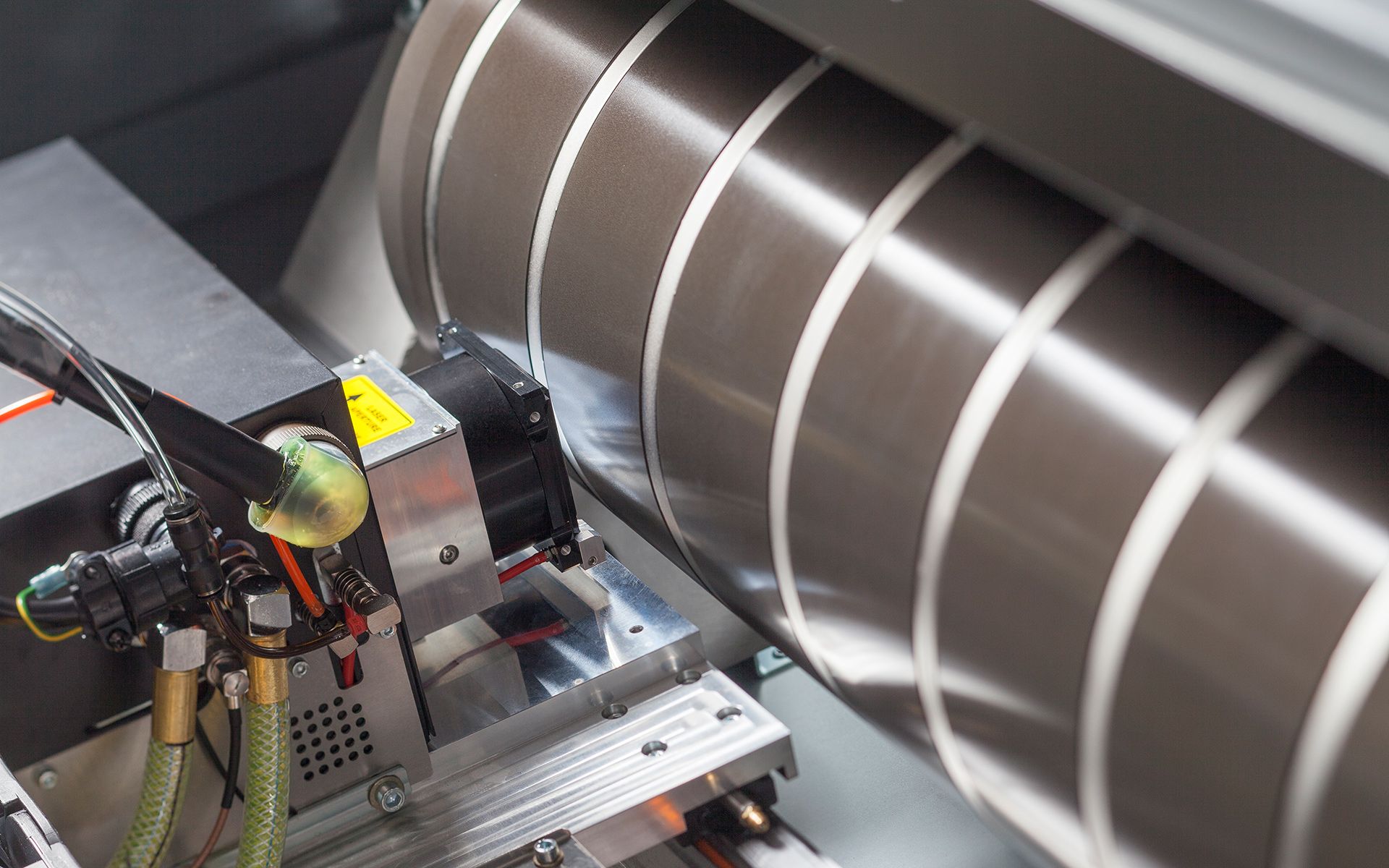

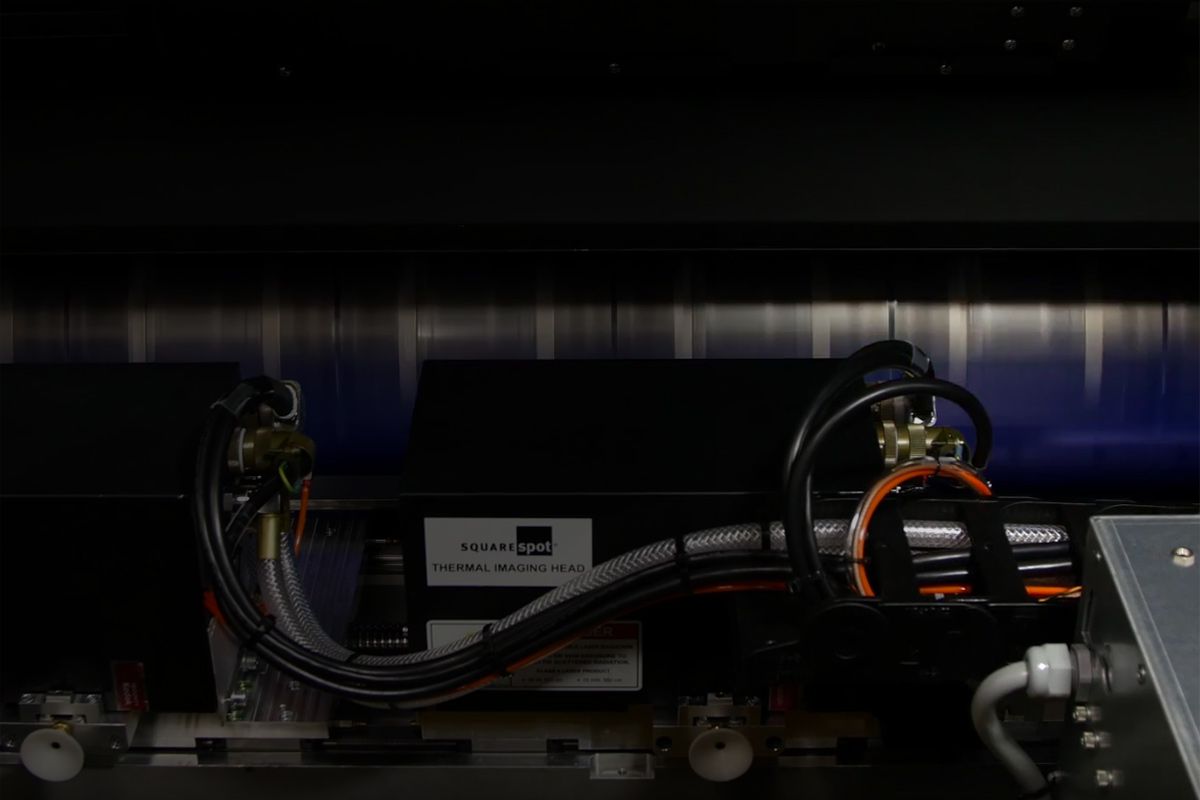

| Technology | 830 nm platesetter with KODAK SQUARESPOT Imaging Technology, external drum | |

| Automation options |

|

|

| In-line punch option |

|

|

| Performance specifications | Q400 Platesetter | Q800 Platesetter |

| Throughput at 2400 dpi 2,3 plates per hour (pph) |

For plate size 724 x 838 mm

Standard and Auto Unload:

|

For plate size 1,030 x 838 mm

Standard and Auto Unload:

|

| Repeatability | ± 5 microns between two consecutive exposures on the same plate left on the drum | |

| Accuracy | ± 20 microns between two plates imaged on the same device | |

| Registration | ± 25 microns between image and plate edge | |

| Workflow connectivity | Standard KODAK Print Console with TIFF Downloader Software included; connects to KODAK PRINERGY Workflow and most third-party workflow systems. JDF/JMF Connectivity Option enables functionality in the Print Console software to provide job and device status. | |

| Imaging specifications | Q400 Platesetter | Q800 Platesetter |

| Resolution |

|

|

| Screening |

|

|

| Maximum plate size: around drum x along drum 4 | 838 x 990 mm |

|

| Minimum plate size: around drum x along drum 4 |

|

|

| Maximum image area: around drum x along drum | 827.9 x 990 mm |

|

| Physical characteristics | ||

| Size (H x W x D) / Weight |

|

|

|

1 Cannot be combined with in-line punch system. 2 Imaging speed and throughput is dependent on media sensitivity. All values are for media sensitivity of 120mJ/cm 2 3 Tested with KODAK Workflow Solutions. For additional information about the test conditions, please consult your Kodak representative. 4 Standard plate gauge is 0.15 to 0.3 mm (0.006 to 0.012 in). Option available for plate gauge of 0.15 to 0.4 mm (0.006 to 0.016 in). The 0.40 mm plate size is only supported for the “SA” manual device, or in manual bypass for the AU, AL, SCU and MCU. For plate gauges 0.15 to 0.2 mm (0.006 to 0.08 in) there may be some differences in min and max. plate sizes. For more information, please consult your Kodak representative. 5 Minimum plate size around drum is 383 mm with the plate rotation option, and minimum plate size for manual bypass is 305 x 215 mm. The platesetter is a Class 1 Laser Product and fully complies with EN60825-1 and US Federal Regulations 21 CFR 1040.10 - CDRH. |

||

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.