Multiple automation options

Latest Features

Latest Features

Time Tested Technology

| General Specifications | ||

|---|---|---|

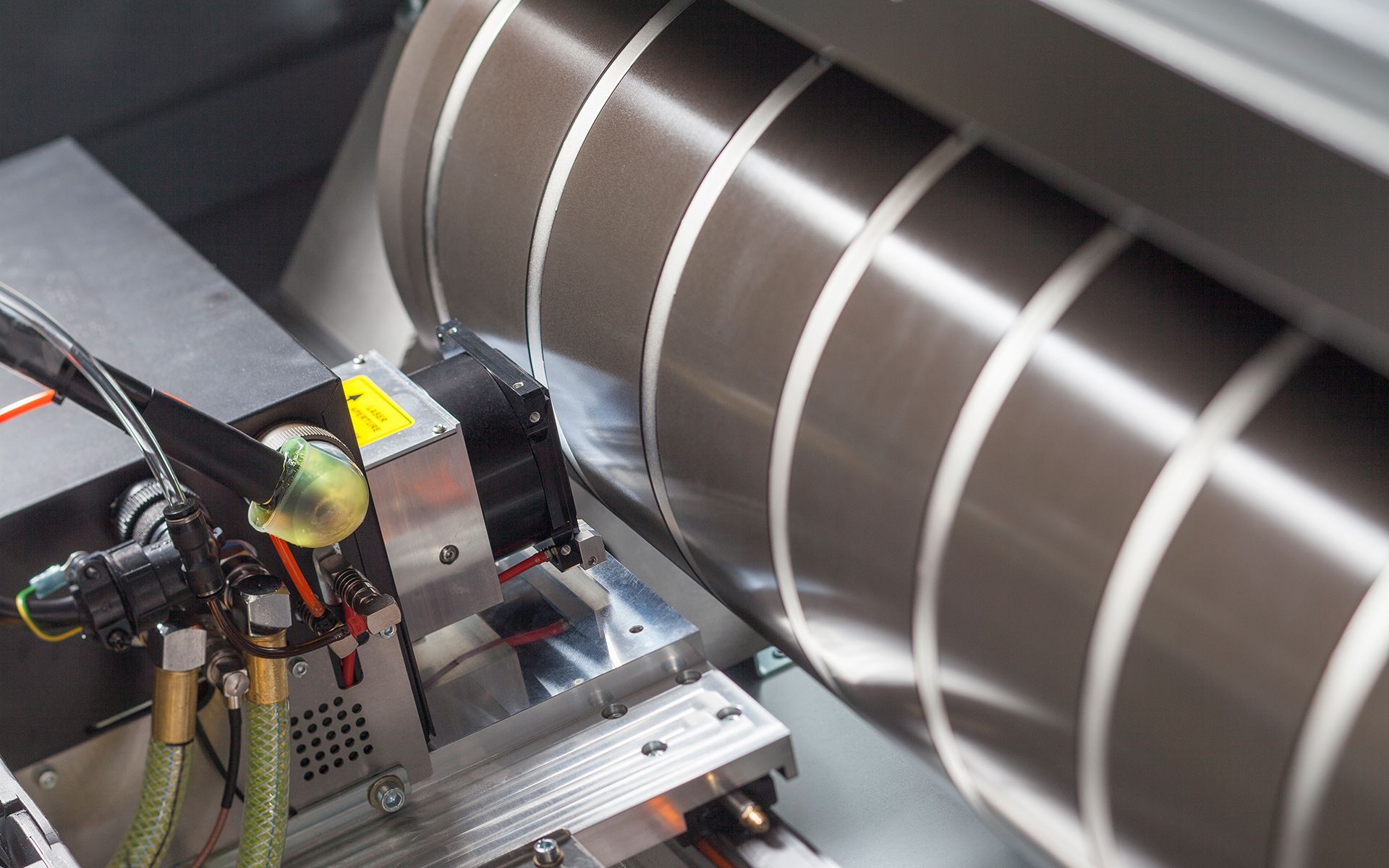

| Technology | 830 nm thermal imaging platesetter, semi-automatic, external drum | |

| Automation options |

|

|

| Performance Specifications | Q2400 Platesetter | Q3600 Platesetter |

| Throughput at 2400 dpi 1,2 for plate size 1,030 x 800 mm |

|

|

| Throughput at 2400 dpi 1,2 for plate size 1,804 x 1,422 mm |

|

|

| Throughput at 2400 dpi 1,2 for plate size 2,083 x 1,600 mm | N/A |

|

| Repeatability 3 | ± 8 microns between two consecutive exposures on the same plate left on the drum | |

| Accuracy 3 | ± 35 microns accuracy of image size and shape | |

| Registration 3 | ± 25 microns between image and plate edge at registration points | |

| Workflow connectivity |

|

|

| Imaging specifications | Q2400 Platesetter | Q3600 Platesetter |

| Resolution |

|

|

| Screening |

|

|

| Maximum plate size:around x along drum 4 | 1,422 x 1,804 mm | 1,600 x 2,083 mm |

| Minimum plate size:around drum x along drum 4 |

|

|

| Maximum image area: around x along drum | 1,408 x 1,804 mm | 1,586 x 2,083 mm |

| Physical characteristics | ||

| Size (H x W x D) |

|

|

| Weight |

|

|

|

1 Imaging time is dependent on media sensitivity and screening type. Throughput shown for KODAK TRILLIAN SP plates. 2 Tested with KODAK Workflow. 3 Specifications pertain to performance at largest plate size, over full temperature range. 4 Standard plate gauge is 0.2 to 0.4 mm (0.008 to 0.016 in.) The platesetter is a Class 1 Laser Product and fully complies with EN60825-1 and US Federal Regulations 21 CFR 1040.10 - CDRH. |

||

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.