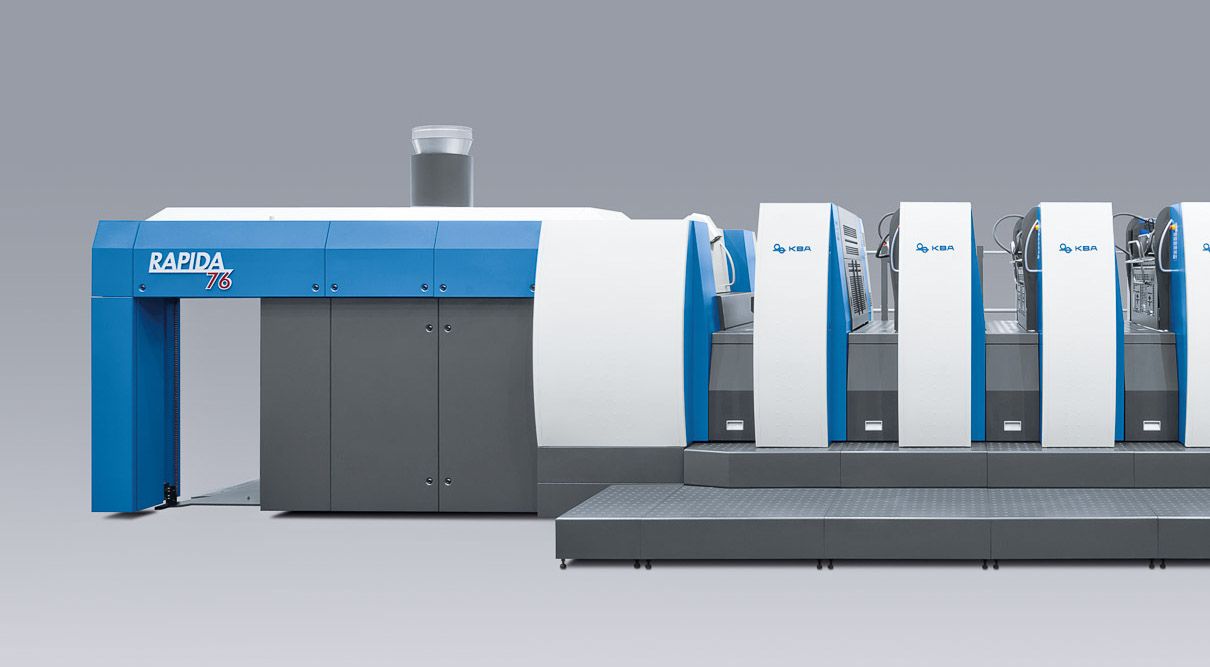

رپیدا 76

اتوماسیون کامل در ماشین چاپ افست دو ورقی

ماشین چاپ رپیدا ۷۶ استاندارهای جدیدی در ماشین های چاپ افست دو ورقی آورده است. با این ماشین چاپ، بسیاری از ویژگی های منحصر به فرد کونیگ اند باوئر و تجهیزات اتوماسیون آنها در ماشین های اندازه دو ورقی هم در دسترس هستند. سیستم تغذیه کاغذ بدون نشان، قابلیتهای تنظیم ماشین از قبل و به طور اتوماتیک و امکانات حتی منعطف تر هم برای اطمینان خاطر هر چاپخانه داری با ماشین دو ورقی کافیست.

محدوده هرچه وسیع تری از کاربردها

رپیدا ۷۶ یک ماشین چاپ بسیار کارآمد برای چاپ انواع متنوعی از کارهای چاپی است. مثلا در چاپ بسته بندی این ماشین با حداکثر ۱۰ برج چاپ، انواع کوتینگ ها، امکان استفاده از پایل های بلند و قابلیت چاپ روی طیف گسترده ایی از مواد چاپی در صدر ماشین های دو ورقی قرار گرفته است. حداکثر سرعت چاپ ۱۸۰۰۰ ورق در ساعت یک معیار دیگر برای برتری این ماشین چاپ است.

ویژگی های برجسته ماشین چاپ رپیدا ۷۶

- • سیستم تغذیه کاغذ بدون نشان، درایوترونیک اس آی اس

- • سیستم شناسایی اتوماتیک پلیت و رجیستر کردن آن

- • قابلیت تنظیم قبل از شروع کار از طریق کنسول ارگوترونیک

- • ترمز کاغذ دینامیک در قسمت تحویل

• سیستم تعویض همزمان پلیت (SPC) تمام پلیت ها را در کمتر از یک دقیقه تعویض می کند.

• فرآیندهای شستشوی همزمان با استفاده از تکنولوژی کلین ترونیک، زمان تعویض کارهای چاپی را به طور قابل ملاحظه ایی کم می کند.

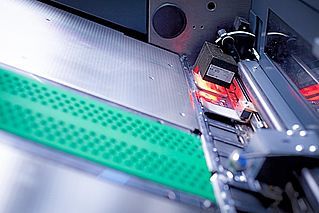

• سیستم منحصر به فرد "سنسوریک اینفید" (درایوترونیک) بیشترین دقت در ورود کاغذ، ثبات در عملکرد تغذیه و بالاترین بهره وری در چاپ را دارد.

قابلیت تنظیم تمام مراحل ماشین چاپ، تضمین کننده دقت آن است و زمان انتقال از یک کار به کار دیگر را به حداقل می رساند.

امکانات اختیاری کنترل رنگ کوالیترونیک و پی دی اف چک، به سرعت محتوا را کنترل و رنگ ها را چک می کنند. بدین ترتیب میزان باطله خیلی کمتر می شود.

• مشخصات بسیار قابل تغییر و قابل تعیین تا ۱۰ برج چاپ و برج ورنی

تولید چشمگیر و بهره وری اقتصادی

با سرعت چاپ حداکثر ۱۸۰۰۰ ورق در ساعت، رپیدا ۷۶ بیشترین میزان تولید را در بین ماشین های چاپ دو ورقی دارد. میزان انعطاف این ماشین برای چاپ در روی انواع متنوع ماده چاپی نیز ویژگی برجسته این ماشین است. ضخامت مواد چاپی مورد استفاده در مدل استاندارد از ۰/۰۴ تا ۰/۸ میلیمتر است و تقریبا تمام مواد مورد استفاده در چاپ تجاری و چاپ بسته بندی را پوشش می دهد. این ویژگی مناسب اکثر کاربردها است.

به همین ترتیب رپیدا ۷۶ را می توان با تجهیزات اختیاری متنوع سفارش داد که امکان نصب تا ۱۰ برج چاپ و عملیات تکمیلی را دارد. انواع گوناگون کوتینگ از کوتینگ تمام سطح چاپی تا جلوه های ویژه و کوتینگ های موضعی، همچنین امکان استفاده از پایل بلند و استفاده از سیستم های خشک کن مقرون به صرفه VariDry تنوع بیشتری به کارهای چاپی رپیدا ۷۶ می دهد.

سیستمهای اندازه گیری و کنترل در این ماشین چاپ کیفیت بالای چاپ را تضمین می کند و میزان باطله را به حداقل می رساند.

سریع ترین زمان آماده سازی

با سیستم کاملا اتوماتیک تعویض پلیت FAPC، پلیت ها بدون هیچ وقفه ایی تعویض می شوند و چون این تعویض همزمان با زمان آماده سازی ماشین انجام می شود زمان صرف شده بسیار کوتاه است. به کمک قابلیت DriveTronic Plate Ident پلیت به محض اینکه داخل ماشین چاپ شود شناسایی می شود و رجیسترها قبل از چاپ اولین نمونه تنظیم می شوند. شستشوی همزمان نوردها؛ لاستیک ها و سیلندهای چاپ روند آماده سازی را هرچه سریع تر می کنند

تکنولوژی برتر در بین سایر ماشین های دو ورقی

رپیدا ۷۶ ماشین چاپی است که در بالاترین سطح تکنولوژی کار می کند. انتقال آرام و مستقیم کاغذ و قابلیتهای کامل تنظیم در این ماشین از ویژگیهای برجسته آن است.

بالاتر از همه ویژگیهای بالا، خارج کردن برج های چاپی که استفاده نمی شوند از روند کار چاپ است. با این ویژگی مقدار باطله کاغذ و میزان مصرف مرکب کم می شود و زمان کمتری برای شستشوی لاستیک ها لازم است. همچنین رپیدا ۷۶ به کنسول ErgoTronic با صفحه نمایش بزرگ و رابط اپراتوری مجهز است.

سیستم های تجهیزات جانبی و مدیریت تولید در رپیدا ۷۶ هیچ نیازی را بدون پاسخ نگذاشته است.

| Standard | Optional |

|

|

|

|---|---|---|---|---|

| حداکثر اندازه کاغذ | ۵۳۰x۷۵۰mm | 605 x 750 mm |

|

|

| حداکثر سرعت تولید ۱ | 16.000 sheets/h | 18.000 sheets/h |

|

|

| ضخامت ماده چاپی | 0,04 - 0,6 mm | 0,04 - 0,8 mm |

|

|

| تعداد برج های چاپ | 2 - 10 | - |

|

|

| Sidelay-free infeed DriveTronic SIS |

ü |

- |

|

|

| تعویض کاملا اتوماتیک پلیت FAPC |

ü |

- |

|

|

| واحد پشت و رو زنی | - |

ü |

|

|

| راهنمای کاغذ ونچوری |

ü |

- |

|

|

| CleanTronic washing systems | - |

ü |

|

|

| سیستم خشک کن وری درایر | - |

ü |

|

|

| قسمت تحویل با ترمز دینامیک کاغذ ایرترونیک |

ü |

- |

|

|

| راهکارهای لجستیکی کونیگ اند بائر | - |

ü |

|

|

| کنسول با رابط تاچ ترونیک ارگوترونیک |

ü |

- |

|

|

| سیستم های اندازه گیری و کنترل کیفیت | - |

ü |

|

|

| ماجول پشتیبانی فنی آنلاین و از راه دور ۲۴ ساعته | - |

ü |

|

|

| راهکارهای نرم افزاری برای گرفتن سفارش اینترنتی | - |

ü |

|

1 بسته به سایر پارامترها از قبیل مرکب و ماده چاپی مورد استفاده

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.