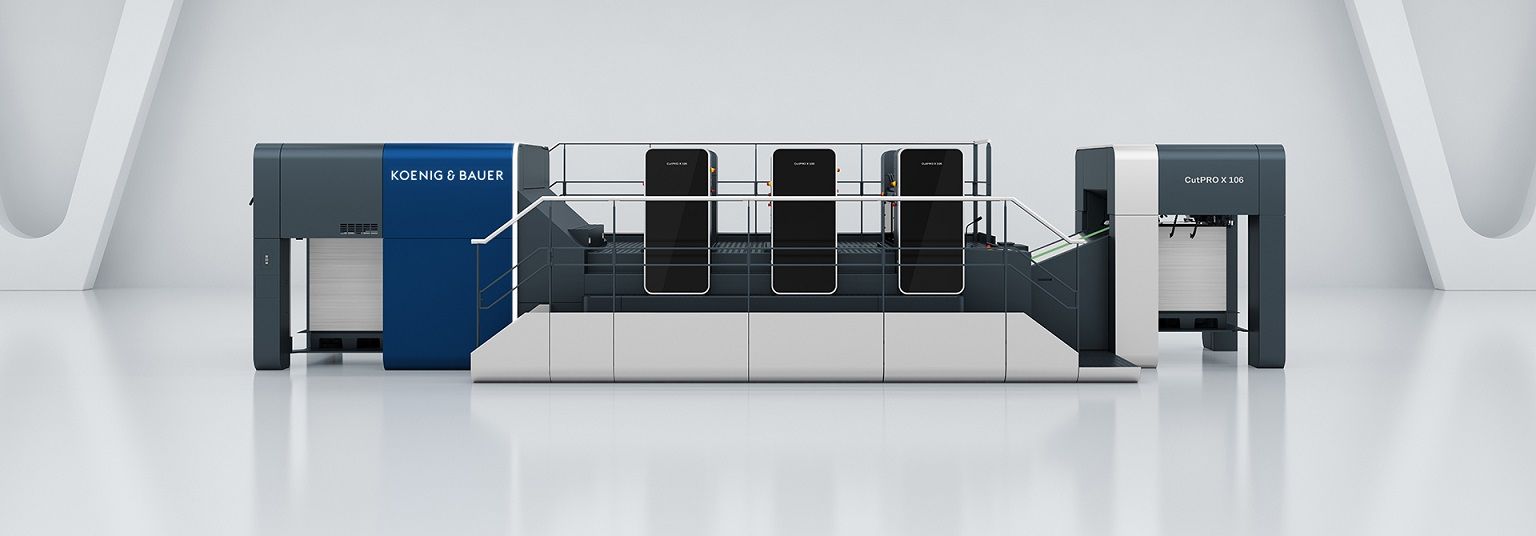

کات پرو ایکس 106

کارآمدی رپیدا در دایکات

ماشین روتاری دایکاتر کات پرو ایکس ۱۰۶ به ورقهای چاپ شده شکل می دهد. این ماشین که براساس پلتفرم شناخته شده ماشینهای چهارونیم ورقی رپیدا شاخته شده است، تکنولوژی بسیار جدید دایکات را در طیف نامحدودی از عملیات تکمیلی اعمال می کند. دایکات، امباس کردن، پرفراژ، خط بریل بر روی بسته بندی های دارویی، پوشه های ظریف و فانتزی یا برچسبهای خاص، همه و همه قابل انجام است.

ماشینی طراحی شده برای نیازهای آینده

ویژگیهای فنی نظیر سیستم تغذیه درایوترونیک، انتقال کاغذ ونچوری، سیستم های یکنواخت پنجه و تحویل ایرترونیک کارآمدی چشمگیر دایکات را فراهم می کنند. برای چاپ با کیفیت و دایکات با دقت بسیار بالا شما می توانید از بین طیف کامل تجهیزات و ترکیب های مختلف، ماشین موردنظر خود را بسته به نیازهای شخصی خود انتخاب کنید.

ویژگی های برجسته کات پرو ایکس ۱۰۶

- اتوماسیون سطح بالا برای تعویض سریع کارهای چاپی

- اپراتوری به کار گرفته شده در پلتفرم رپیدا

- ترکیب های کارآمد ماشین برای طیف وسیع کاربردها

- کارآمدی بسیار بالا و قابل مقایسه با دایکات های تخت

* از ۲۴ ژ وئن ۲۰۲۰ میلادی ماشین رپیدا آر، سی، دی۱۰۶ تحت نام جدید کات پرو ۱۰۶ ایکس عرضه می گردد.

کارآمدی بالا با سرعت دایکات حداکثر ۱۵،۰۰۰ ورق/ ساعت

سرعت دو برابری تولید ماشین در مقایسه با فرآیندهای سنتی تولید

اتوماسیون خلاقانه برگرفته شده از رپیدا ۱۰۶ - قهرمان بلامنازع آماده سازی و تعویض کارهای چاپی

طراحی ماشین با توجه به نیازهای خاص مشتریان برای چاپ طیف وسیع و متنوع محصولات

امکان تعویض سریع پالت ورق های چاپ شده برای دایکات، بدون هیچگونه کار دستی - یک مزیت برجسته برای تولید لیبل های آی ام ال

بخش های مختلف مجزا از هم برای سهولت اپراتوری، قابلیت انعطاف و کیفیت مثال زدنی

تنوع حداکثری در مواد چاپی مورد استفاده در کات پرو ایکس ۱۰۶

ماشین کات پرو ایکس ۱۰۶ یک ماشین حقیقتا همه جانبه در کاربردهای متنوع از چاپ لیبل تا چاپ تجاری و چاپ بسته بندی می باشد.

طیف تولیدات این ماشین از فیلم های بسیار نازک IML تا مقوای به ضخامت ۰/۷ میلیمتر را شامل می شود.

بسته به برنامه ایی که برای ماشین طرح شده است، می توان از بین طیف بسته بندی های ویژه، بسته بندی دلخواه را انتخاب کرد. این برنامه ها کار دایکات را حتی با کاغذهای نازک و حساس با حداکثر سرعت ۱۴،۰۰۰ ورق در ساعت انجام می دهند.

زمان آماده سازی بسیار کوتاه

در ماشین های کات پرو ایکس ۱۰۶ به خاطر ماجول های اتوماسیون که در آن تعبیه شده فاصله زمانی آماده سازی کار با دایکات آن بسیار کم است. مثلا زمان لازم برای تعویض کامل کار بیشتر از ۱۵ دقیقه طول نمی کشد.

اطلاعات هر کار یا از طریق درگاه یو اس بی و یا از طریق تنظیم اطلاعات از طریق سی آی پی لینک یا لوگوترونیک پروفشنال به ماشین منتقل می شوند.

جداسازی ورق ها و انتقال آن ها به داخل ماشین سریع و بسیار دقیق است. تکنولوژی درایوترونیک کات پرو ایکس ۱۰۶ که در بخش تغذیه این ماشین به کار گرفته شده، سهولت کار اپراتوری و کوتاه بودن زمان آماده سازی را تضمین می کند.

تعویض قالب دایکات تقریبا در ۲ دقیقه انجام می شود. این کار بدون ابزار و ساده با دنبال کردن دستورالعمل های تعویض قالب انجام می گیرد. یک سنسور لیزری قالب دایکات را اسکن می کند تا ماشین بتواند ضخامت قالب را در تنظیمات اتوماتیک مشخص سازد. بدین ترتیب مرحله زمان بر تنظیم دقیق قالب دایکات حذف می شود.

درضمن تمام تنظیمات مربوط به هر کار دایکات را می توان ذخیره کرد تا در کارهای بعدی مورد استفاده قرار گیرند. بدین ترتیب در کارهای تکراری در زمان تنظیم کار صرفه جویی می شود.

نتایج عالی دایکات

قلب واحد دایکات در این ماشین یک سیلندر مغناطیسی است. دقت کار این سیلندر +، - ۵ میکروثانیه است. مگنت های دائمی تنظیم و ثابت نگهداشتن قالب دایکات را تضمین می کنند.

یک سیستم رجیستر اضافی امکان تنظیم سریع و دقیق قالب را فراهم می سازد. با رجیستر جانبی، محیطی و قطری تنظیمات دقیق نسبت به کاغذها انجام می شود.

دقت نهایی دایکات توسط کنترل دقیق فشار بین فرم دایکات و سیلندرها انجام می گیرد. این فشار از طریق پنل اپراتوری ارگوترونیک صورت می گیرد.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.