The bottleneck for efficient short-run finishing is not the running speed of a folder gluer. Rather, the crucial factor is: How fast is the changeover to the next job? With the TAS principle, the KAMA FlexFold 52i makes the changeover in just a few minutes:

1. Transfer the job data (networked data exchange)

2. Activate Auto-Move

3. Start production

The impressively fast changeover results from the electronic transfer of job data from the network via the JobManager software and, first and foremost, from the automatic changeover of the entire folder gluer to the next job. Only the blanks are inserted manually. Further time savings: the FlexFold 52i moves all modules directly to the appropriate positions, without reference runs, which are necessary elsewhere.

With its high level of automation, the FlexFold 52i is very easy to operate and new staff is quickly trained.

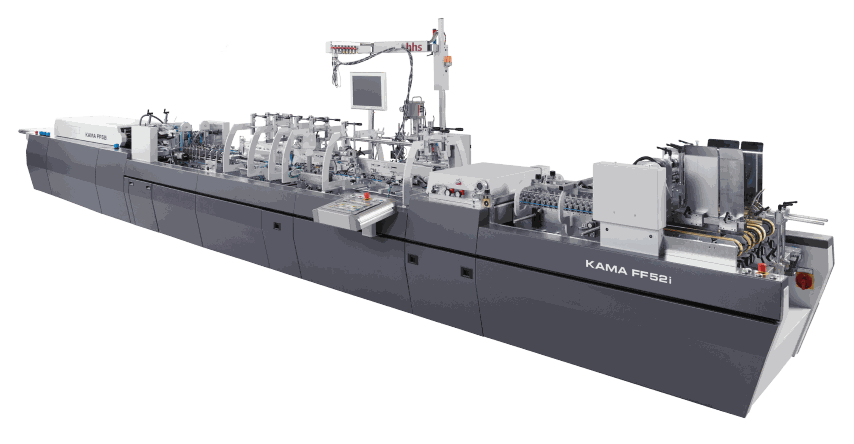

FlexFold 52i

The world's first folder-gluer for short runs and digitally printed packaging

Cost-effective production of digitally printed folded cartons and small SKUs: this is the booming market for which we have developed the FlexFold 52i. The first folder-gluer for short runs is fully automatically adjustable and delivers order changeovers in a record time of just a few minutes. This means that the FlexFold 52i can handle far more than a hundred orders per day – whether straight-line boxes, cushioned packaging or lock bottom boxes.

The KAMA FlexFold 52i is tailor-made for print shops and packaging manufacturers who want to offer the following services to large brand manufacturers, but also to regional brands and local suppliers:

Digitally printed folded cartons in changing designs with seasonal, regional or event-specific image designs (e.g. food or fashion)

Personalised and individualised packaging (e.g. cosmetics and pharmaceuticals)

Cartons in different languages (e.g. pharmaceuticals and healthcare)

Partial orders – saving costs and keeping things up to date at all times

Folded cartons with shorter time-to-market

The innovative FlexFold 52i machine received the EDP Award 2017 for the “Best folded carton solution” (European Digital Print Association).

1. Transfer the job data (networked data exchange)

2. Activate Auto-Move

3. Start production

The impressively fast changeover results from the electronic transfer of job data from the network via the JobManager software and, first and foremost, from the automatic changeover of the entire folder gluer to the next job. Only the blanks are inserted manually. Further time savings: the FlexFold 52i moves all modules directly to the appropriate positions, without reference runs, which are necessary elsewhere.

With its high level of automation, the FlexFold 52i is very easy to operate and new staff is quickly trained.

FlexFold 52i

The world's first folder-gluer for short runs and digitally printed packaging

Cost-effective production of digitally printed folded cartons and small SKUs: this is the booming market for which we have developed the FlexFold 52i. The first folder-gluer for short runs is fully automatically adjustable and delivers order changeovers in a record time of just a few minutes. This means that the FlexFold 52i can handle far more than a hundred orders per day – whether straight-line boxes, cushioned packaging or lock bottom boxes.

The KAMA FlexFold 52i is tailor-made for print shops and packaging manufacturers who want to offer the following services to large brand manufacturers, but also to regional brands and local suppliers:

Digitally printed folded cartons in changing designs with seasonal, regional or event-specific image designs (e.g. food or fashion)

Personalised and individualised packaging (e.g. cosmetics and pharmaceuticals)

Cartons in different languages (e.g. pharmaceuticals and healthcare)

Partial orders – saving costs and keeping things up to date at all times

Folded cartons with shorter time-to-market

The innovative FlexFold 52i machine received the EDP Award 2017 for the “Best folded carton solution” (European Digital Print Association).

KAMA

For over 125 years, engineers at KAMA have been developing high-quality finishing die cutters and folder-gluers for the global market.

As a well-established, reliable partner for cutting and finishing processes, we offer a wide range of profitable solutions for small and medium-sized conventional print runs as well as for digital printing. With more than 500 installations in 80 countries the innovative KAMA machines "made in Germany" are in demand around the world - in the commercial print market and also in packaging.

For over 125 years, engineers at KAMA have been developing high-quality finishing die cutters and folder-gluers for the global market.

As a well-established, reliable partner for cutting and finishing processes, we offer a wide range of profitable solutions for small and medium-sized conventional print runs as well as for digital printing. With more than 500 installations in 80 countries the innovative KAMA machines "made in Germany" are in demand around the world - in the commercial print market and also in packaging.