- Predictive maintenance

- Thorough testing with 20 pilot users

- Enhanced availability and transparency

- Predictive maintenance adds a further layer to the service concept

Koenig & Bauer has successfully launched its predictive maintenance services for printing press owners. Various workflows have been elaborated and implemented in close cooperation with more than 20 pilot users from the newspaper and commercial segments. The objective of predictive maintenance is clearly defined. “We use the information contained in already existing press data for automated analyses. This makes it possible to identify and rectify potential problems before they occur,” says Thomas Potzkai, head of service at Koenig & Bauer.

Service managers are provided with full details of the situation on a given press. On this basis, arrangements can be made for remote maintenance interventions or service calls, as necessary. A technician subsequently rectifies the fault within the framework of a scheduled assignment, averting the risk of unplanned stoppages. Any necessary downtime is scheduled for an already production-free period. The customer benefits from greater production reliability and increased press availability.

It is possible to assess a wide range of press components, for example the plate changers, the reel stands, or the hydraulic clamping and lubrication systems. Predictive maintenance applies artificial intelligence methods, such as rule mining or machine learning, to enable precise and automated real-time analysis of the press data. Even otherwise hidden processes and interactions of components or internal networks on the press line are subjected to systematic evaluation.

One of the first new customers was WE-Druck from Oldenburg in the north of Germany. Three years ago, the company invested in a new Commander CL from Koenig & Bauer. Margit Schweizer, senior manager at WE-Druck: “Predictive maintenance gives us peace of mind. We cannot afford sudden stoppages and unscheduled downtimes. Our customers expect us to deliver top quality within the agreed deadlines.”

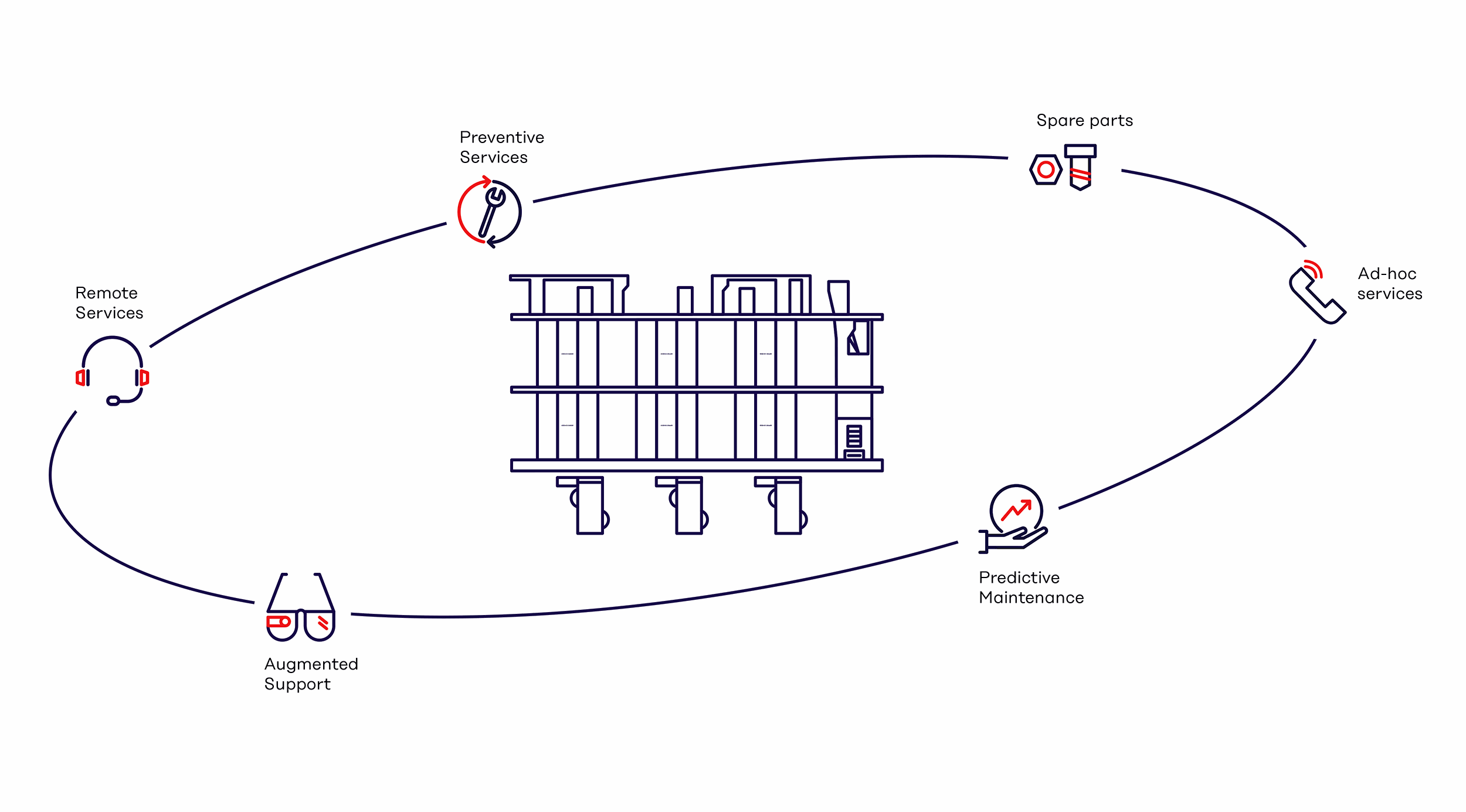

Predictive maintenance as part of the overall concept

Predictive maintenance adds a further dimension to the Koenig & Bauer service concept. Together with spare parts, Visual PressSupport, ad-hoc service calls and a whole program of remote and preventive services (periodic maintenance and inspection), Koenig & Bauer is able to offer its press customers the best possible support. In addition to Koenig & Bauer’s newspaper and commercial web offset presses, the single-pass digital press RotaJET and presses of the CorruJET, CorruCUT and CorruFLEX series also benefit from predictive maintenance. Similar services are also available for presses supplied by the other business units of Koenig & Bauer.