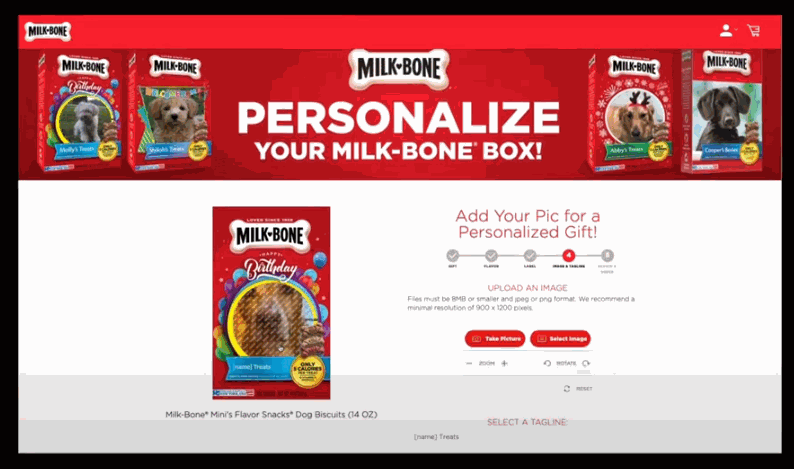

In addition to producing some of the world’s best preserves, peanut butters and coffees, The J.M. Smucker Co. is a major force in the pet care market. One of its most iconic pet brands, Milk-Bone, has been a trusted treat for dogs for well over a century. The Milk-Bone marketing team recently recognized that a consumer trend toward personalization presented an opportunity for the brand—offering customizable Milk-Bone boxes that allow consumers to personalize the label with a picture of their own furry family member.

Smucker was quick to recognize digital packaging’s potential to engage consumers and bolster brands. They formed a technical task force comprised of marketing and R&D personnel to evaluate digital print technologies and determine their suitability for the various campaigns they were considering.

PROSPER delivers the whole package

Naturally, the team was concerned with print quality and cost, but they had an additional concern regarding throughput. Smucker operates on a national scale and requires large volumes even for promotional activities.

“We helped the Smucker team run trials on every known digital technology from toner to inkjet,” said Ed Zumbiel, President of Zumbiel Packaging. “All the digital devices provided great print quality but most came up short in terms of cost effectiveness and productivity. When the Smucker team visited our shop to run trials on the KODAK PROSPER 6000S Inkjet Press, they were immediately convinced that Kodak’s unique continuous inkjet technology was the process that best fit their needs.”

The Smucker team saw not only graphic quality that was indistinguishable from their current lithographic cartons, they also saw remarkable productivity: their cartons run digitally at 600 feet per minute. They were impressed by the speed of the Kodak technology and could not seem to take enough video footage of the press in action. Smucker also appreciated the fact that the PROSPER’s water-based inks are food safe and far superior to lithographic inks in terms of sustainability and color reproduction.

“In short,” said Zumbiel. “The KODAK PROSPER was the first digital device that ‘checked all the boxes’ for the Smucker team.”

A streamlined process

It is one thing to offer personalized packaging, and quite another to execute

and deliver quickly and flawlessly. The J.M. Smucker Co.’s technical and

marketing teams worked closely with Zumbiel and Kodak over a period of months

as they developed their web-to-print e-commerce portal, variable graphics

workflows and internal logistics. In the end, each carton contains four

variable elements: background (standard and holiday copies), pet photograph,

pet name, and variable barcode (for order tracking and downstream shipping

label generation).

Smucker batches images and text collected from its website and transmits them electronically to Zumbiel, who in turn utilizes variable data software to combine and map the graphics prior to digital printing. The process of converting thousands of variable images into printable files is highly automated and takes less than twenty minutes to transfer, assemble and RIP the files.

Once files are ready, Zumbiel’s unique digital PROSPER Press configuration featuring inline substrate priming, digital printing and high-speed die-cutting (over 15,000 Milk-Bone cartons per hour) makes short work of print production. To further compress production cycle times and reduce machine set-up costs, Zumbiel dedicated a folder-gluer to Milk-Bone production. Cartons come straight off the digital press and directly into the gluer. The result is a total cycle time from receipt of files to shipment of finished Milk-Bone cartons in about two hours.

The additional benefit of

marketing buzz

From a marketer’s perspective, the program will cost effectively drive traffic

to the Milk-Bone website and create instant buzz on social media as consumers

post images of their lovable dogs on the front of Milk-Bone boxes. Since its

launch, custom Milk-Bone cartons have already been highlighted on NBC’s Today show,

and a host of celebrities have posted pictures of their cherished pets’ custom

boxes on Instagram and Facebook.

Creating custom folding cartons for dog treats places Milk-Bone and Zumbiel in uncharted territory -- neither can predict just how large the program will become. “One thing is certain,” said Zumbiel. “Our solution based on Kodak technology has proven that digital print is a great option for brands that want to harness the power of personalization.”