To enable users to answer the ever higher quality demands and expectations of their customers, Rapida presses can be equipped with a diversity of quality measurement and control systems. These systems contribute to faster makeready, help to reduce waste, and ensure constant high quality in print production.

Register measurement and control

Koenig & Bauer offers three different systems for register measurement and control. One thing which all three have in common: They all permit measurement of the lateral,

circumferential and diagonal register. In accordance with the individual requirements of your print company, you can choose between the compact hand-held measuring device ErgoTronic ACR, convenient console-based register control with ErgoTronic ICR and the automated inline solution QualiTronic ICR.

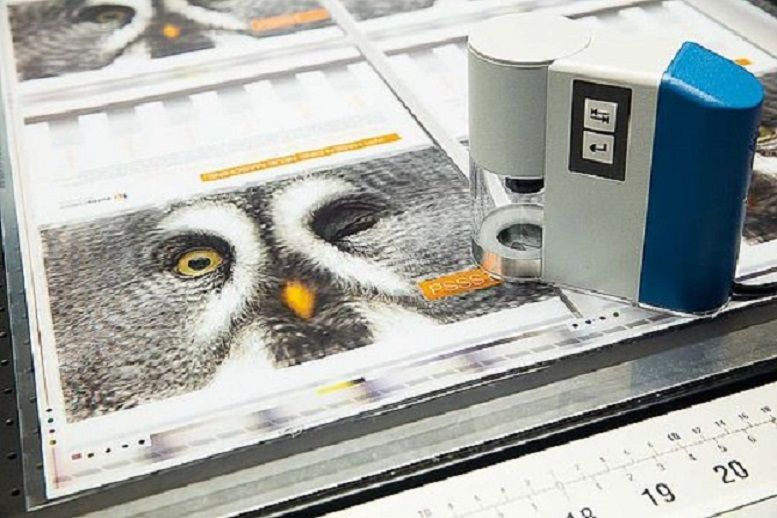

Multifaceted colour measurement

Koenig & Bauer offers three different systems for colour measurement and control. These system are ErgoTronic ColorDrive, ErgoTronic ColorControl and QualiTronic ColorControl. The choice is yours – among a diversity of variants for online or inline control. From an entry-level system to installations with special functions and extensive options. With direct integration into the console or a separate desk. With optional functions from measurement reports to control based on grey balance. Density or Lab values. There are practically no limits.

Sheet inspection inline

Rapida sheetfed offset presses can be equipped with any of three system variants for sheet inspection, as appropriate for your individual production requirements. These systems differ in terms of resolution and identify even the tiniest differences and defects in a printed image.

The systems are: QualiTronic PrintCheck, QualiTronic PDF Check, QualiTronic PDF High Res.