Printing engineers are frequently involved in heated debate regarding the factors that influence the results achieved by a particular printing method, especially in offset printing. This debate largely centres on the press and the relevant printing process because this is where all the components needed for printing come together. However, the print result also always reflects the interplay between the materials and resources used and the operating personnel. This series of articles will explain the various factors separately and describe them in detail.

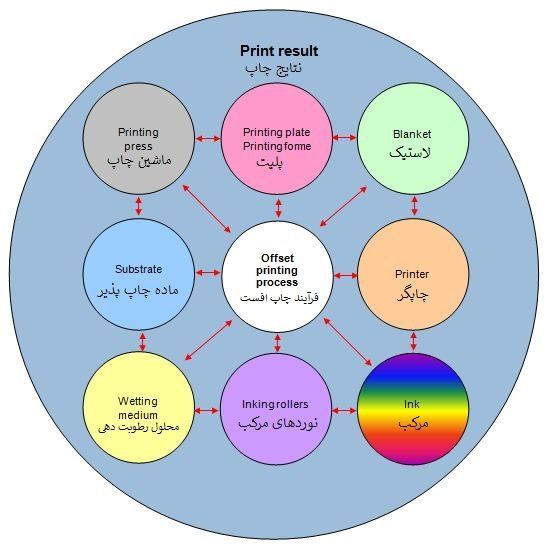

The diagram below shows the most important factors. The pressroom climate is an additional factor, but this will not be considered due to the significant regional differences.

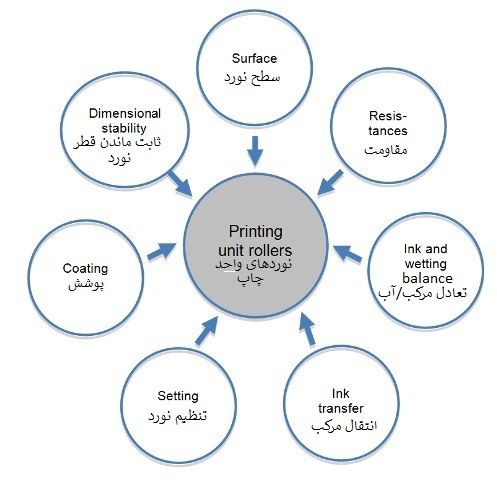

Each of these factors has a significant impact on the print result and is directly linked to the other parameters. While the last edition of Gallus In Touch took a closer look at printing plate parameters, this issue will focus on rollers parameters. This article looks at the rollers in the printing unit. In the offset printing unit, this means the rollers in the inking and wetting units.

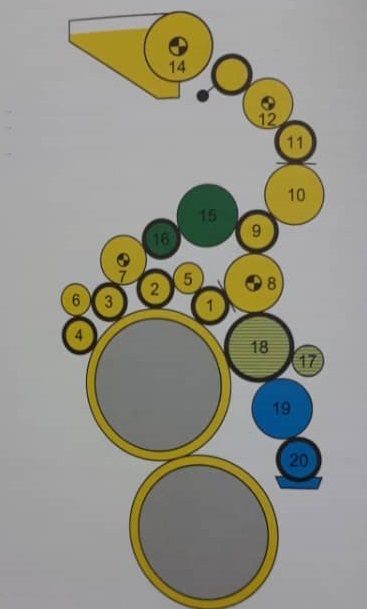

Rollers in the inking unit:

There are essentially two different types of rollers in the inking unit:

1. Ceramic roller- distributor

2. Rubber rollers

There are two main groups of rubber rollers – transfer rollers and forme rollers.

The vibrator roller transfers the ink from the ink duct to the inking unit.

Rollers in the dampening unit

A number of different roller materials are used in the dampening unit. The fountain roller and the forme-damping roller are coated with rubber, the dosing roller is coated with chrome, and the remaining wetting unit rollers can be coated with chrome, rubber.

Roller settings

Precise roller settings are all-important for ensuring a constant feed of ink and dampening medium. They should always comply as closely as possible with the machine manufacturer's specifications and must be adhered to. The settings of the dampening rollers are far more important than those of the inking unit rollers.

The setting of all forme rollers in relation to the printing plate and distributor rollers is also vital. The forme rollers play a key role in the quality of printing plate dampening ng and the inking up of the printing forme.

The roller settings influence the following:

- Ink transfer from the ink duct

- Ink dosing

- Ink transport in the inking unit

- Wetting of the printing plate

- Ink/water balance in the inking unit

- Constant ink and water feed

Roller care

Roller care is very important for maintaining consistently high print quality. The roller cleaning fluid must clean the rollers quickly and thoroughly but must not attack roller surfaces. The roller surface must maintain a good grip because smooth rollers do not transfer ink as effectively. The cleaning fluid must not cause the rollers to swell or shrink, nor should it attack the printing plate.

The roller manufacturer or machine supplier can offer advice on which cleaning fluids and care products to use.