- Fast makeready and high job productivity

- Enormous product variety thanks to extensive accessories

- Quality standards at the highest level

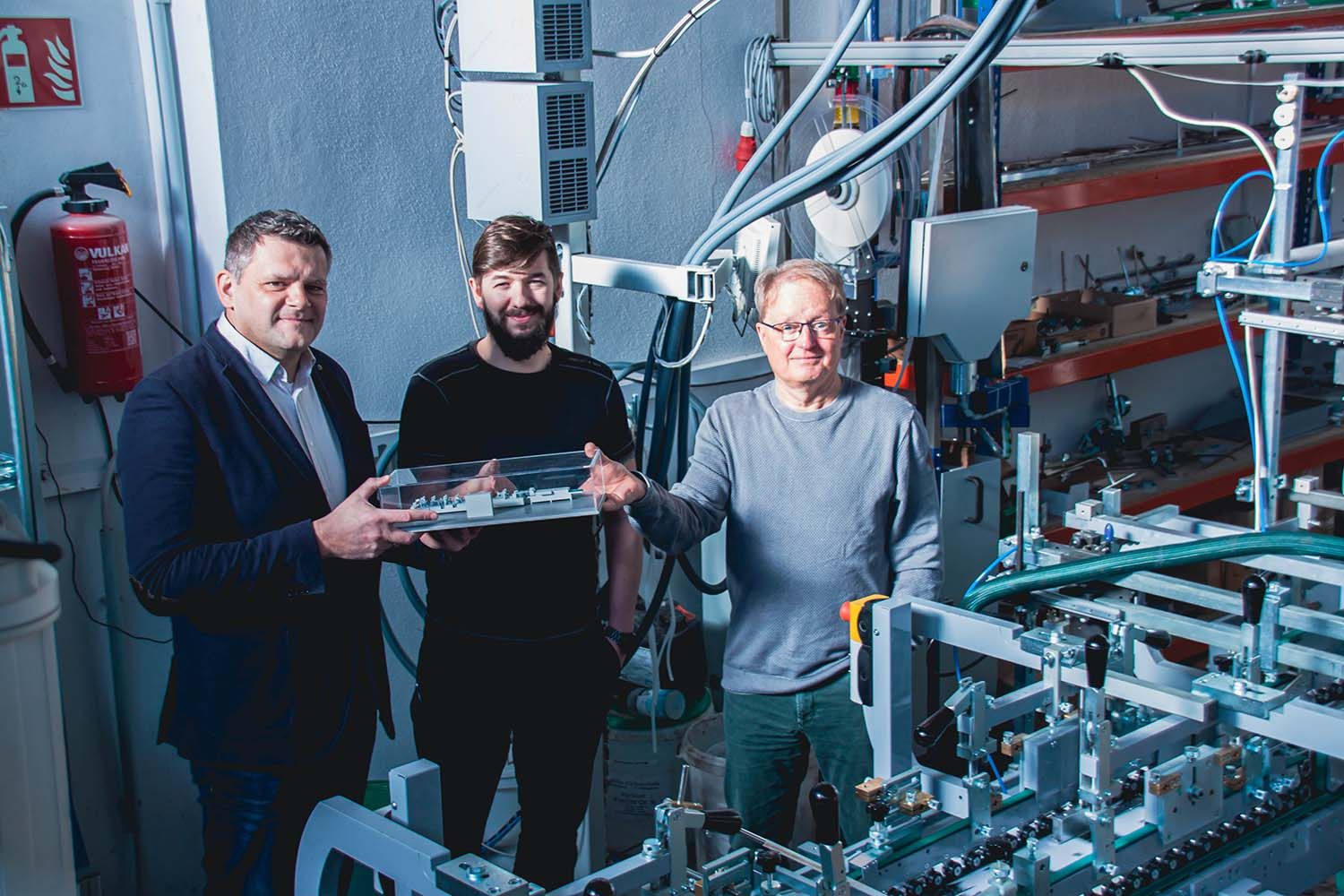

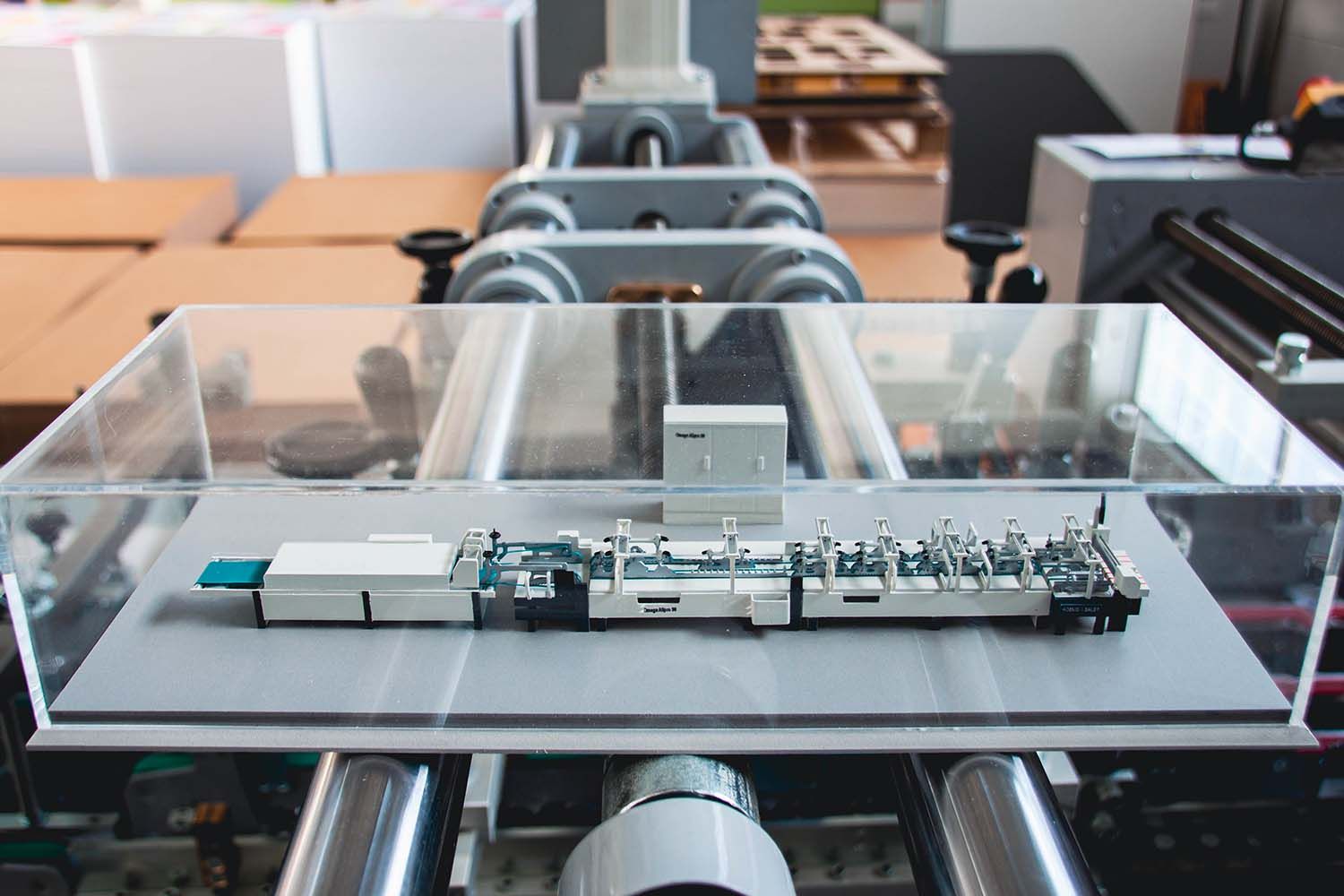

Ronny Neugärtner (left) from the sales team at Koenig & Bauer (DE) presents a model of the Omega Allpro 90 to Guido Heidel, the owner of Hagl-Stanztechnik, and to customer advisor Hans Willbrger.

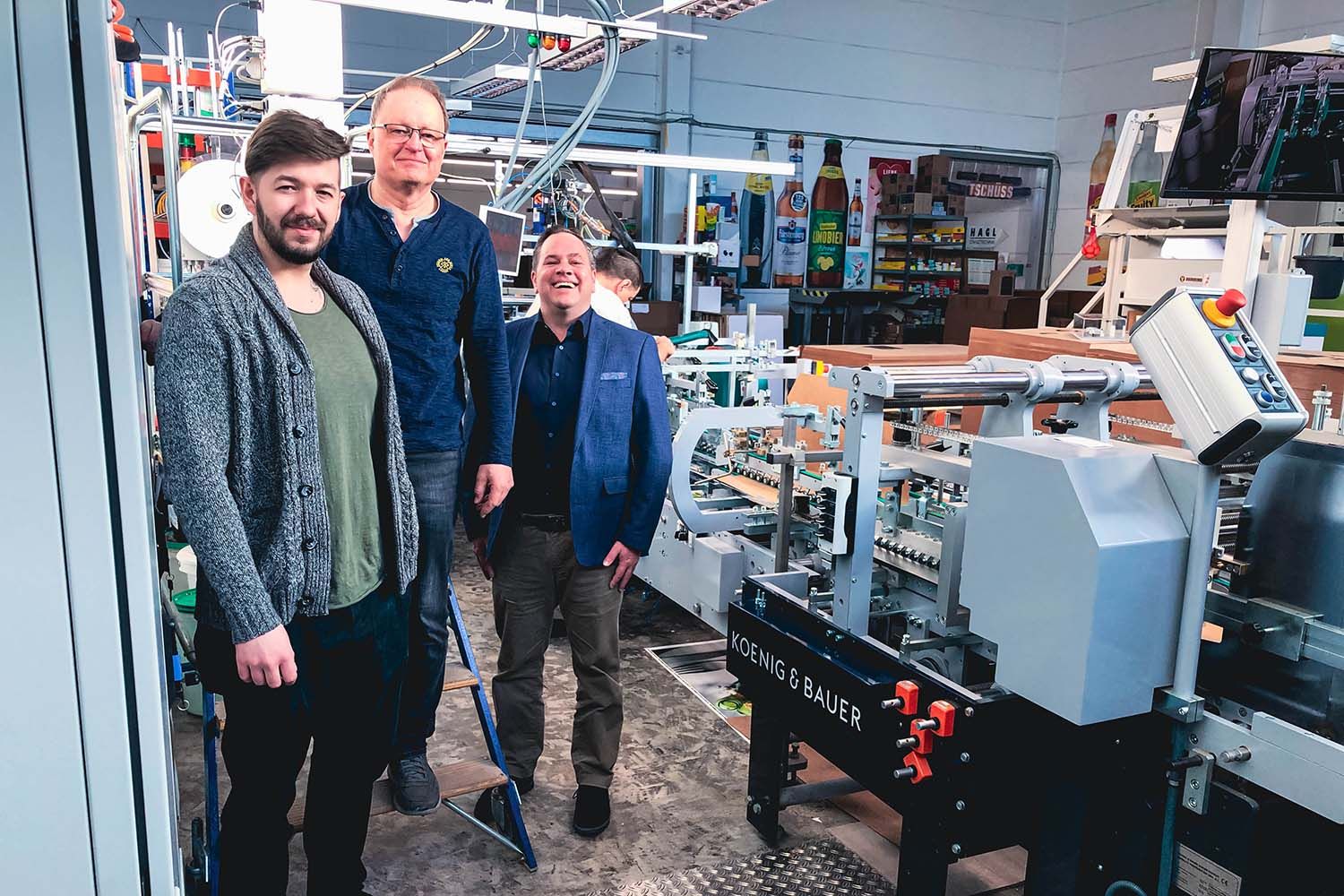

Over the last few months, Hagl-Stanztechnik in Puchheim near Munich has had no reason to complain about a shortage of work. And a new Omega Allpro 90 folder-gluer from Koenig & Bauer is now helping to process the incoming orders quickly. It has accelerated makeready by several orders of magnitude in comparison to the predecessor machine. At the same time, production output has increased significantly. And yet another increase is on the way: with the installation of a new packer in February, production on the machine is now even faster.

Hagl-Stanztechnik began as a contract die-cutting workshop in the 1980s and has been active as a specialist service provider for board and paper processing since 2004. The company has attached great importance to meeting the highest quality standards right from the very beginning. It also handles products that other companies prefer to outsource, whether due to the substrate thickness, the format or delicate processing requirements such as extra-tiny nicks. Examples include hangers with rounded corners and cut-outs for clothing, beverages and other products. The employees at Hagl – most of whom are printers or print technicians – regularly face the challenge of finding ways to implement the tricky processing solutions without blowing the client’s budget.

Equipment features for a diverse product portfolio

When his previous folder-gluer started to show its age, company owner Guido Heidel decided to look around for alternatives. His attention was caught by the Allpro, and in particular by its level of variability, which extends far beyond the scope of standard products. Accessories are available to cover a broad spectrum of applications. Almost all parts of the machine can be loosened and retightened with a single tool. That greatly simplifies makeready processes. The memory functions for repeat jobs are another key benefit. And the machine control system for the Allpro delivered to Hagl has been adapted specifically to the company’s production needs.

The list of products that are now being handled on the Allpro 90 ranges from envelopes for hotel key cards to bottle hangers requiring special gluing variants, and also extends to large folding cartons with crash-lock bases.

From small to maximum format

Guido Heidel is especially fascinated by the feeder: the blanks are transported into the machine as if by magic. Suction belts that can be activated are equally impressive when the machine is running special gluing variants. “We are known for our production of out-of-the-ordinary products in top quality. Mere quantity is not really our business,” says Heidel. The Allpro is a perfect fit for this philosophy.

Hagl-Stanztechnik is now able to offer products in larger formats. Where 70 cm used to mark the end of the road, 90 cm is possible today. And this format is also utilised to the full. Even so, there are no restrictions on production in very small formats down to approx. 35 × 50 mm.

Alongside this production flexibility, Guido Heidel points to another, purely practical, reason for choosing the Omega Allpro 90. It is a European product, and so any spare parts that may become necessary can be obtained at relatively short notice, without long waits for overseas delivery. This is supplemented by the accessibility of Koenig & Bauer’s dense service network.

Specialist for intricate product details

The majority of Hagl-Stanztechnik’s customers are print companies from practically all regions of Germany. When things get complex, Puchheim is their first port of call. Together with Guido Heidel and his team, solutions are then developed for unusual and complicated post-press processing options. Sometimes Koenig & Bauer also has to step in to help source the special tools that are necessary.

It is a huge advantage that Hagl’s post-press specialists speak the language of the printers. This almost always enables them to find a feasible and, above all, economical way to implement the desired product. At the same time, younger office and production colleagues are glad to receive support from the experienced team at Hagl, and typical mistakes such as an inappropriate running direction or incorrect flap dimensions can be avoided from the outset.

Moreover, a window-gluing machine with hot-creasing unit and corner puncher enables windows to be incorporated around the corner of a folding carton. There are only a few companies that own machines this special. And they are even rarer among those who handle contract work.

Hagl-Stanztechnik also serves a number of its own customers – in some cases, throughout the entire process chain from packaging design to the finished product. Wherever the jobs come from, Guido Heidel makes a point of not simply supplying a product, but instead implementing the customer’s wishes to a T. At Hagl-Stanztechnik, the aim is to demonstrate – wherever possible – what is feasible in product conversion and finishing. mind, your story will ring false and be bland. No one will be interested. Write for one person. If it’s genuine for the one, it’s genuine for the rest.