- UL’s ECOLOGO Certification follows rigorous testing and formulation assessments

- Inks used in SPC Delta 130 FlexLine Automatic minimize environmental impact

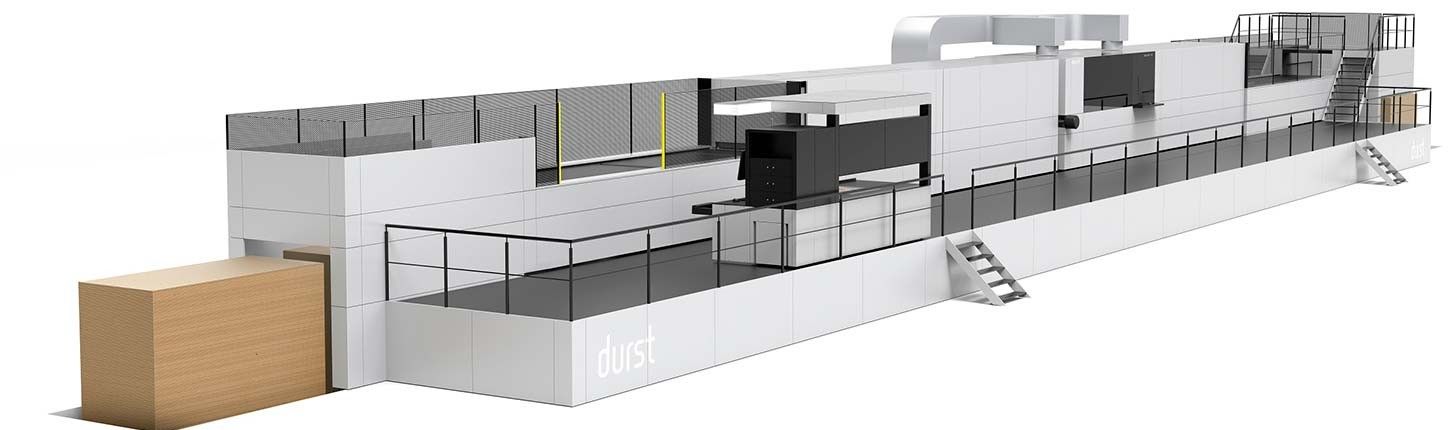

- Koenig & Bauer Durst demonstrates industry leadership and superior sustainable performance

Koenig & Bauer Durst has announced today that its food safety water-based printing inks have successfully achieved UL ECOLOGO® Certification, demonstrating third-party validation of the products’ sustainability performance.

The Durst WT Food SP Ink and the Durst WT Food MP Ink product lines meet rigorous lifecycle-based environmental performance criteria as defined in UL’s stringent ECOLOGO Standard (2801 – 2012 Standard for Sustainability for Printing Inks). Black, cyan, light cyan, magenta, light magenta and yellow inks have all been assessed and include no hazardous components defined by the ECOLOGO Standard.

The products achieved UL ECOLOGO Certification following the evaluation of multiple criteria throughout a product’s life including energy use, waste disposal, and toxic reductions, among other areas. Using proprietary water-based ink technology, the inks are designed with core technologies to provide automated, productive, food safe printing systems.

The inks are used in Koenig & Bauer Durst’s Delta SPC Flexline Automatic 130 press. The WT Food SP Ink was designed for fast print processes on corrugated materials and is used for the single-pass print line. It can be used to realize high quality, odorless, abrasion-resistant, glossy and light-fast corrugated products that precisely meet requirements of the packaging industry. The WT Food MP Ink is used in multi-pass printing.

UL works to advance global sustainability, environmental health, and safety by supporting the growth and development of environmentally preferable products, services and organizations.