Depart

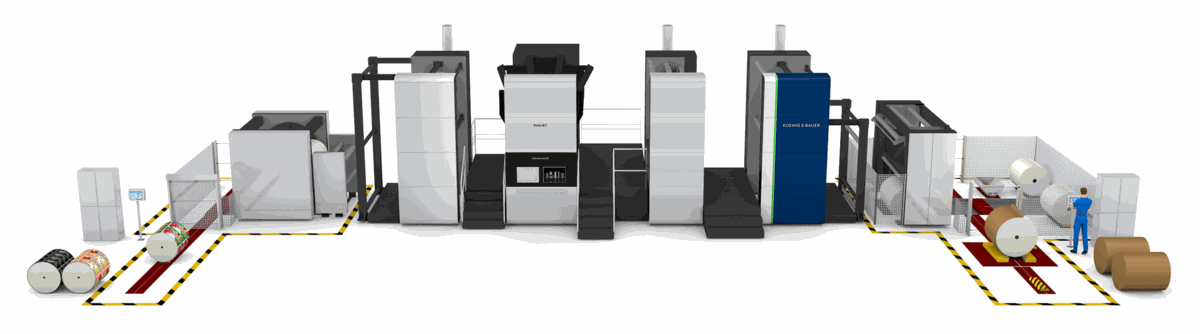

Folding cartons, flexible packaging, decors, books and much more: The RotaJET is suitable for various applications. The high-performance system for industrial digital printing is based on a modular platform. But it is even more: the single-pass press combines the company's tradition and innovation with its more than 200-year history.

Here is an example: The widest RotaJET has a printing width of 2250 mm. In this configuration, 416 print heads with 2048 nozzles each - a total of 851,968 nozzles - are responsible for a perfect printed image. At a frequency of 54 kHz, the RotaJET achieves the incredible figure of 2,760,376,320 droplets per minute with full coverage of all four colors. Figures that are impressive. On the other hand, they require above all innovative strength and precision. For example, the print heads are aligned to each other with an accuracy of less than five micrometers. One micrometer - that corresponds to one thousandth of a millimeter. By comparison, a thin hair is 0.03 mm thick. It quickly becomes clear that not only bits and bytes, but also steel and iron must fit together absolute precisely.

Innovation and tradition

For more than a decade, Koenig & Bauer has been developing the Single-Pass Digital Printing Machine further and further. And the sales successes prove that the Group was right to take this step into digital printing. This year alone, Koenig & Bauer is installing two more RotaJETs at leading packaging companies.

The RotaJET incorporates many tried-and-tested technical features from Koenig & Bauer's existing machine series. The precise and exact web guiding of the substrate within the machine was, for example, taken over by the newspaper presses. Another example is the non-stop changing of substrate rolls at full speed and a low waste rate of just under five meters For years, Koenig & Bauer has been offering EcoSPLICE, a fully automatic gluing preparation device.

Another well-known and long-proven component is Patras – the modular system for material logistics from Koenig & Bauer is one of the world’s most comprehensive system for all types of printing presses. More than 2000 systems have been installed at customers‘ sites in the past decades. Substrate rolls with a diameter of up to 1800 mm, a roll width of up to 2800 mm and a maximum roll weight of 6 tons can be transported fully automatically without any problems. The modular concept allows flexible adaptation to specific production requirements and space conditions. Accordingly, this system can be transferred to the RotaJET without any problems.

There are virtually no limits to the range of colors that can be used thanks to synergies with other business units in the Koenig & Bauer Group. With flexo printing units in front of or behind of the RotaJET’s digital printing unit, spot or special-effect colors can be integrated into the print image. Thanks to the precise web guiding and innovative ideas of the design engineers, the different printing processes are coordinated with each other and thus achieve exactly the desired result. Cameras inspect and document every printed meter.

Another well-known and long-tested part is Patras - the modular system for materials logistics from Koenig & Bauer is one of the world’s most comprehensive systems for all types of printing presses.

Different substrates for different products

From tissue paper to solid board, the RotaJET is capable of printing on a wide variety of substrates - packaging, decors, posters, leaflets, folding boxes, books or coffee bags. “We have arrived in almost all important market segments in digital printing”, says Christoph Müller, Member of the Board of Koenig & Bauer. “Worldwide our RotaJET is unique and one of the most powerful digital printing systems on the market. A glance at the supermarket shelves is enough to understand the diversity of packaging variants. Sustainability, time-to-market and the ever-shrinking print runs with an increasing number of variants are the requirements of our customers that we can address with the RotaJET.”

With its different web widths from 777 mm to 2250 mm, the RotaJET series is designed for a wide range of relevant formates in the packaging sector. The expandable and modular design can be customized for different applications and the on-the-fly job changeover allows efficient production of even the smallest quantities. This means that on-demand production, special interest and even personalized packaging can be implemented economically. At the same time, the water-based and food-safe inks developed specifically for the RotaJET contribute to sustainability and environmental protection.

In the area of decor printing, section lengths of over five meters are possible. This opens up completely new possibilities for Koenig & Bauer customers that do not yet exist with other technologies. The maximum productivity is 35,000 m2 / h. For example, with 220 working days and two-shift operation, the RotaJET prints almost 120 million square meters of paper – the equivalent of 5.6 times the area of Frankfurt Airport.

With flexo printing units in front of or behind of the RotaJET’s digital printing unit, spot or special-effect colors can be integrated into the print image

851,968 Nozzles for a Perfect Printed Image

Rotajet Digital Press Machine

Koenig & Bauer digital printing